Bacis Information

New levels of affordability, ease-of-use and quality in an entry-level 3D printer

Ideal for engineering and jewelry applications, the FabPro 1000 excels at low-volume, small-part prototyping and direct 3D production across a wide range of high-quality materials.

Productivity, Redefined

Produce models in hours, not days. Compared to competing systems, the FabPro 1000 can create higher-quality parts with precision and smooth finish at up to three-times-faster high-throughput print speeds.

Speed and Productivity Comparison

Compare the same part file printed on a full platform at 50 micron to a competitive entry-level system:

FabPro 1000 Print Time: 2.5 hours

Competitive Entry-Level SLA Print Time: 10 hours

Lower Costs, Delivered

3D Sprint file preparation and print management software helps manage material usage with less waste with optimized print builds and support structures. This combination of fast print speeds and optimized printing all leads to lower part costs and lower Total Cost of Operations (TCO).

Industrial Strength with Start-to-Finish Simplicity

This entry-level powerhouse packs industrial durability and reliability into a rugged yet compact platform, delivering professional quality day in and day out. It's also simple to use – from setup, material loading and file configuration to post-processing, cleaning and maintenance:

No special training or certification is required due to an intuitive design and easy-access print chamber.

Replacing print trays and switching materials is a snap.

Post-processing is seamless with an included finishing kit, and optional light-based LC-3DPrint Box UV post-curing unit for required cleaning and curing.

Simple Post-Processing for Perfect Parts

Post-processing for the FabPro 1000 is a simple two-step process – clean and cure. Simply remove the printed part from the FabPro 1000, remove any support structures and clean in a solvent either in an ultrasonic cleaner or manually. The FabPro 1000 includes a Finishing Kit for supplies to help with the cleaning and support removal process.

Applications

An Engineer’s Aid

Rapid prototyping

Design iteration

Functional testing

Mechanical assembly/fit testing

Life testing

Functional parts

Injection molding alternative for small, micro-molded parts (direct printed or RTV molding)

Display models (ready for finishing/painting)

A Jeweler’s Gem

Jewelry pattern production

Investment casting

Prototype pieces

Design verification

Fitting pieces

Master patterns for RTV/silicone molds

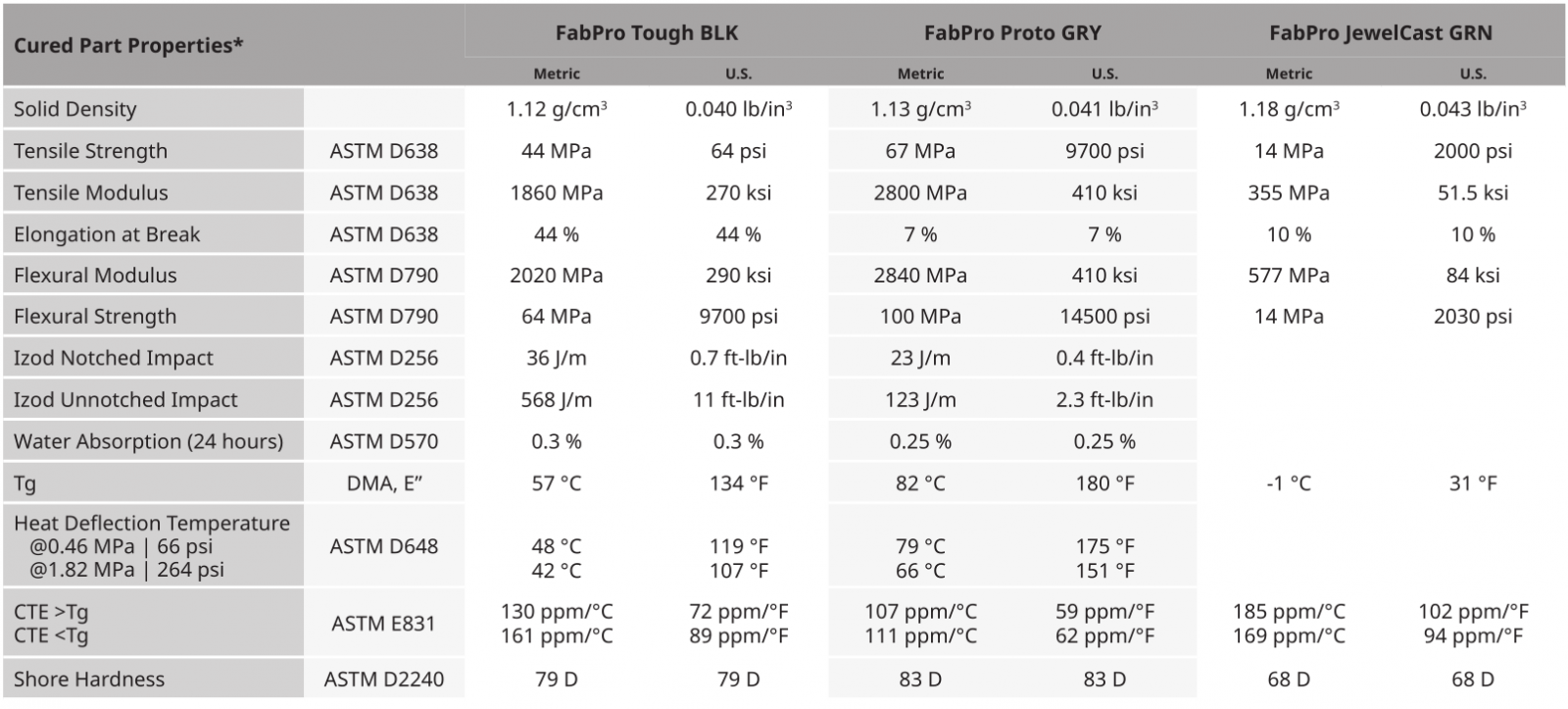

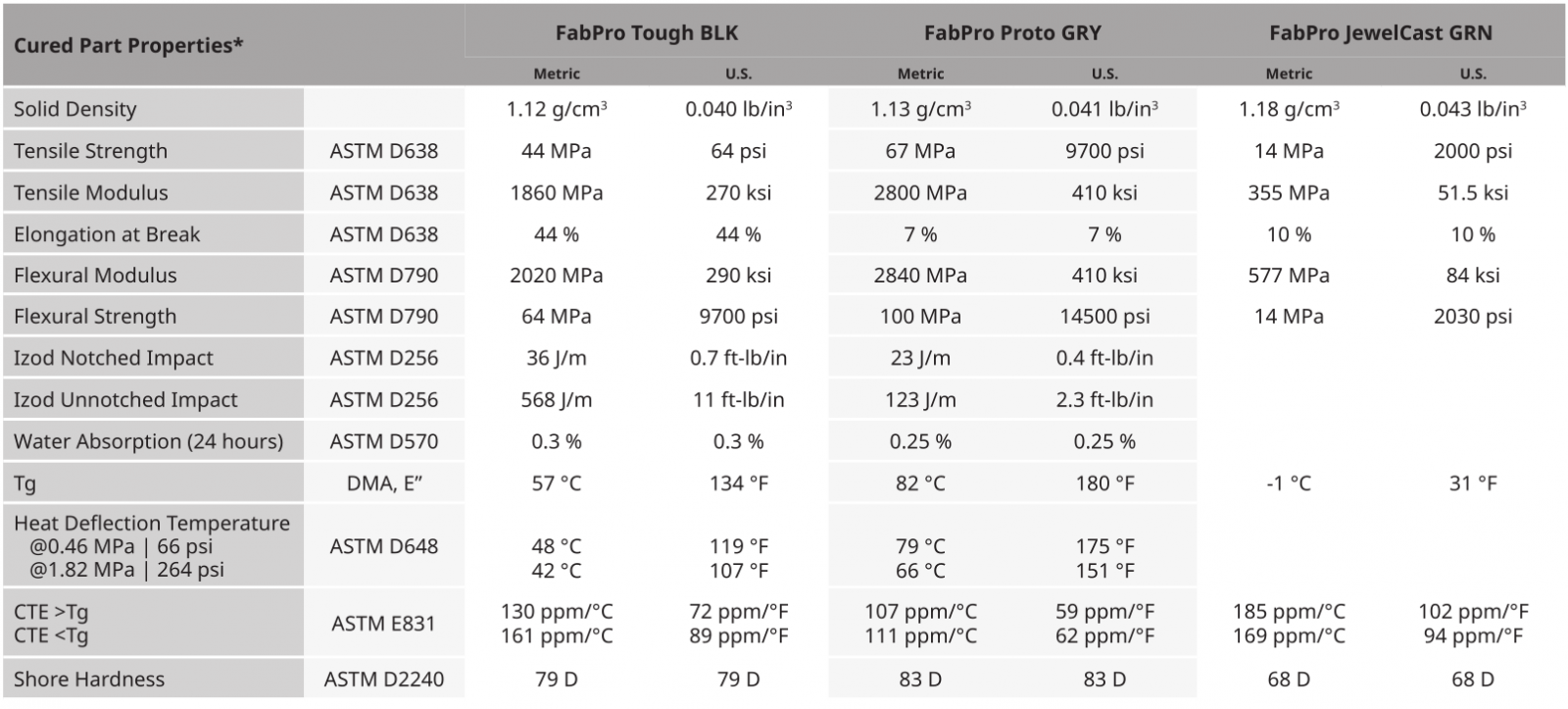

Materials

.png)

.png)

.jpg)