C9: Compact and Cost-Efficient Precision Bending

The C9 is the successor to the widely acclaimed Cone900, offering a compact and economical solution for precision bending. Featuring a single servo-driven ball screw, the C9 provides sufficient forming force to handle most small parts, making it an ideal investment for shops seeking performance without excess capacity.

Its small footprint allows operators to remain seated during operation, ensuring excellent ergonomics and operator comfort. Powered by CoastOne’s signature servo-driven ball screw technology, the C9 delivers high-precision forming with exceptional energy efficiency—averaging less than 1.5 kW in power consumption.

The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance commonly associated with hydraulic press brakes—making the C9 a clean, low-maintenance, and environmentally friendly solution for modern sheet metal fabrication.

C9X: Ergonomic Precision with Expanded Tooling Flexibility

Compared to the standard model, the C9X offers increased vertical clearance, enabling more versatile bending capabilities and a wider range of tooling options. Aside from the added height, the C9X shares the same core specifications as the C9. Its compact design allows operators to remain seated during operation, promoting superior ergonomics and operator comfort.

Powered by CoastOne’s signature servo-driven ball screw system, the C9X delivers high-precision forming with exceptional energy efficiency—averaging less than 1.5 kW in power consumption. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes, making the C9X a clean, low-maintenance solution for precision sheet metal bending.

C12: Increased Bending Force and Capacity

For applications requiring more power, the C12—CoastOne’s larger sibling to the C9—delivers enhanced forming force and extended bending capabilities. Equipped with two servo-driven ball screws instead of one, the C12 effectively doubles the available bending strength. Its longer bending length also allows for forming wider parts with ease.

CoastOne’s signature servo-driven ball screw technology ensures high-precision performance while promoting environmental sustainability. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes—making the C12 a clean, efficient, and low-maintenance solution for precision sheet metal forming.

C12X: Extended Bending Capacity with Enhanced Tooling Flexibility

Compared to the standard model, the C12X offers increased vertical clearance, allowing for more versatile bending capabilities and a broader range of tooling options. Aside from its added height, the C12X shares the same core specifications as the standard C12, including two servo-driven ball screws and a maximum bending length of 1300 mm.

CoastOne’s signature servo-driven ball screw system ensures high-precision forming while promoting environmental sustainability. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes—making the C12X a clean, efficient, and low-maintenance solution for precision sheet metal bending.

C15: Versatile Bending with Compact Efficiency

As the largest model in CoastOne’s C Series, the C15 press brake features two servo-driven ball screws and a generous bending length that accommodates a wide range of part sizes—while maintaining low operating costs. Its compact footprint and flexible capacity make it a cost-effective alternative to larger press brakes.

CoastOne’s signature servo-driven ball screw system ensures high precision and energy efficiency. The absence of hydraulic oil eliminates the need for frequent oil changes, spare parts, valves, and ongoing maintenance typically associated with hydraulic press brakes—resulting in a cleaner, more sustainable solution for precision sheet metal forming.

C15X: Enhanced Versatility with Extended Tooling Capacity

Compared to standard models, the tallest machine in the C Series—CoastOne’s C15X—offers greater flexibility in bending applications and tooling options. Aside from its increased vertical clearance, the C15X shares the same core design as the standard C15, featuring two servo-driven ball screws and a maximum bending length of 1550 mm.

CoastOne’s signature servo-driven ball screw system ensures high-precision forming while delivering exceptional energy efficiency. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes—making the C15X a clean, low-maintenance solution for precision sheet metal bending.

G20: Compact Precision with CoastOne’s Direct Servo Crowning

Like all CoastOne G Series press brakes, the G20 features a rigid O-frame construction that offers significantly lower deflection compared to conventional C-frame designs—while maintaining a lighter structural profile. The G20 is equipped with three servo-driven ball screws, enabling simultaneous crowning and bending operations.

Thanks to the high accuracy of its servo system, the upper beam can be CNC-controlled to dynamically deflect and seamlessly “follow” the lower beam throughout the bending cycle. This proprietary direct crowning system from CoastOne ensures outstanding bend precision and consistency across the entire workpiece.

In addition to its advanced servo kinematics, the G20 offers environmental and operational advantages. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes—resulting in a cleaner, more efficient, and cost-effective solution for precision sheet metal forming.

G25: Precision Bending in a Compact Format

Like all CoastOne G Series press brakes, the G25 features a rigid O-frame design that delivers significantly lower deflection compared to traditional C-frame machines—while maintaining a lighter structural profile. The G25 is equipped with four servo-driven ball screws, enabling simultaneous crowning and bending operations.

Thanks to the high-precision servo system, the upper beam can be CNC-controlled to dynamically deflect and seamlessly “follow” the lower beam throughout the bending cycle. This proprietary direct crowning system from CoastOne ensures exceptional forming accuracy and consistent bend quality across the entire part.

Beyond its advanced servo kinematics, the G25 offers environmental and operational advantages. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes—resulting in a cleaner, more efficient, and cost-effective solution for precision sheet metal forming.

G30: Compact Precision with Advanced Servo Crowning

Like all CoastOne G Series press brakes, the G30 features a robust O-frame structure that offers significantly reduced deflection compared to conventional C-frame designs—while maintaining a lighter overall build. The G30 is equipped with five servo-driven ball screws that enable simultaneous crowning and bending operations.

Thanks to the high precision of its servo system, the upper beam can be CNC-controlled to dynamically deflect and seamlessly “follow” the lower beam during the bending cycle. This proprietary direct crowning system from CoastOne ensures exceptional forming accuracy and consistency across the entire bend length.

In addition to its superior servo kinematics, the G30 offers environmental and operational advantages. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes—making it a cleaner, more cost-effective solution for modern sheet metal production.

G40: Precision Bending with Advanced Servo Technology

Like all models in the G Series, the G40 features a rigid O-frame design that offers significantly lower deflection compared to traditional C-frame structures—while remaining lighter in weight. Equipped with six servo-driven ball screws, the G40 enables simultaneous crowning and bending operations.

Thanks to the high precision of its servo system, the upper beam can be CNC-controlled to dynamically deflect and “follow” the lower beam in real time. This unique mechanism—CoastOne’s proprietary direct crowning system—ensures exceptional bending accuracy and consistency across the entire workpiece.

Beyond its superior servo kinematics, the G40 is also environmentally friendly. The absence of hydraulic oil eliminates the need for costly oil changes, spare parts, valves, and routine maintenance typically associated with hydraulic press brakes.

The Bull Series: A High-Tonnage, High-Precision Forming Solution

Engineered for demanding precision bending applications, the Bull Series features a high-accuracy O-frame structure equipped with Taylor-manufactured ball screws. This configuration ensures exceptional rigidity and repeatability, making it ideal for tight-tolerance forming operations.

With its compact footprint and high tonnage capacity, the Bull Series delivers maximum forming force in minimal floor space—making it the optimal solution for precision sheet metal fabrication where space efficiency and performance are critical.

Customized Heavy-Duty Press Brake – Optima Series

Tailored Engineering

Every Optima machine is custom-built to meet specific customer requirements, ensuring optimal performance for unique applications.

Long-Term Durability

All Ursviken press brakes are designed for decades of precise and repeatable operation.

Many units remain in active service after more than 50 years of use.

Legacy machines can be rebuilt to deliver near-new performance at a fraction of the cost of a new machine.

Automated Punching Line – PivaPunchPCB CNC Punching Center

PivaPunchPCB is the most efficient punching center for symmetrical parts and product families, offering the same flexibility as conventional sheet metal punching systems. It is especially suited for small batch production involving various materials and thicknesses.

Unlike traditional systems, PivaPunchPCB features a unique motion concept. For coil-fed processing, CNC clamps move the material only along the X-axis—one clamp feeds the material forward while the other pulls it through. Punching is performed using thick-turret tools mounted in quick-change tool cassettes, one on each side, which move along the Y-axis across the material.

Wherever possible, dual-tool punching is utilized to maximize efficiency and throughput.

PivaPunch – Flexible CNC Punching Center for Coil-Based Production

PivaPunch is a versatile CNC punching center utilizing standard thick-turret tooling. It supports raw materials up to 6 mm thick, including pre-painted, plastic-coated, galvanized, cold-rolled low-carbon steel, aluminum, and stainless steel coils.

Designed for sensitive materials, the entire Pivatic production line ensures material-friendly processing. Thanks to full automation, operators do not handle the material directly. The system’s optimized technology guarantees high-quality finished parts.

Specialized punching dies can be combined with thick-turret tools to enhance punching, perforating, and embossing capabilities.

Punching tools are stored on mobile tool carts, allowing tool changes in under one minute. Multiple tool sets—such as various perforation patterns, large openings, or embossing dies—can be preloaded and prepared on dedicated carts for rapid changeover.

MPB – Multi-Tool Profile/Panel Bending Machine

The MPB is the world’s longest panel bending machine, engineered to process materials up to 3.0 mm (11 Ga) thick and handle parts up to 8000 mm (26 ft) in length. It enables the fabrication of long and complex components using a single machine—eliminating the need for roll formers, panel benders, or press brakes in combination.

Customer research indicates that the MPB is ideally suited for demanding and intricate profile applications such as doors, door frames, lockers, shelving, electrical enclosures, and housings. As a highly advanced bending system, the MPB offers customizable control console configurations and a wide range of bending tools to meet diverse production needs.

It features interpolated motion in both X and Y axes and is equipped with an electric drive system for simplified maintenance, programming, and control. Thanks to its innovative design and servo-electric actuation, the MPB also delivers significantly reduced energy consumption.

PivaBend – Material-Friendly Wing Bending Technology for Pre-Coated Panels

Utilizes a wing-style bending method that is gentle on materials, making it especially suitable for pre-painted or coated surfaces.

All edges are bent simultaneously in a continuous process, significantly reducing cycle time.

Each corner of the bending unit is fully programmable for flexible part geometries.

Parallel edges are bent concurrently after positioning, ensuring exceptional dimensional accuracy.

The unique bending technique results in minimal tool wear, extending tool life and reducing maintenance.

Optimized for profiles, panels, and wrap-style components.

Seamlessly integrates with downstream processes such as welding and clinching.

PivaBend for Panels – High-Speed Automated Panel Bending Solution

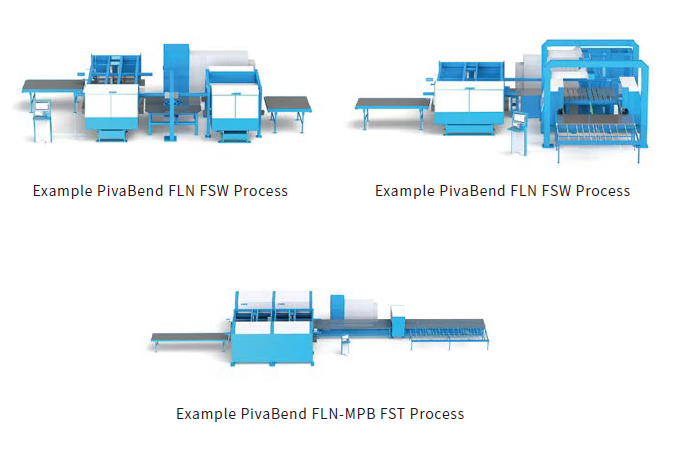

The PivaBend system begins with a profile bending line module and integrates either the PivaBend FSW or PivaBend FST for end bending operations.

With the FSW unit, material flow can be redirected ±90° without flipping the part, or rotated 90° via a turntable to maintain linear flow.

In a continuous production cycle, all four panel edges can be bent simultaneously using dedicated bending units for each side, achieving cycle times as low as 15 seconds per panel.

For parts exceeding 3000 mm (120 inches) in length, a through-type FST bender is required for end bending.

Advanced Automation Features

The PivaBend FSW can be equipped with an automatic hold-down tool organizer to accommodate varying part widths.

Width changeovers are managed automatically by the line control system.

Programming for the next part can be prepared in advance during active production, ensuring seamless transitions.

Post-Bending Handling Options

Finished panels can be discharged manually, via robot, or with a Pivatic stacking unit.

Panels may also be transferred directly to downstream processes such as spot welding, clinching, or assembly.

Customized Production Line – Scalable, Efficient, and Reliable

High Throughput: Engineered for maximum production capacity to meet demanding output requirements.

Flexible Manufacturing Capability: Adaptable to various part geometries and production volumes.

Energy Efficiency: Designed with power-saving technologies to reduce operational costs.

Low Maintenance Requirements: Simplified system architecture minimizes downtime and service needs.

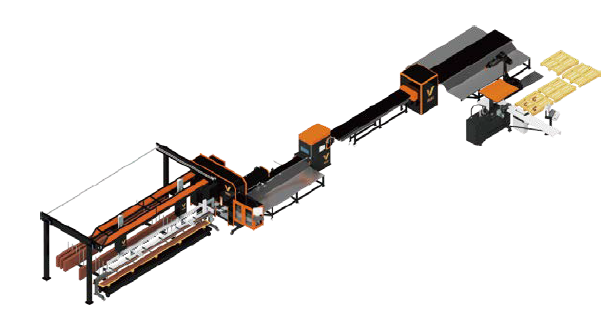

World’s Only Servo-Electric Punch Press: A pioneering solution in flat bar processing.

Reduces energy consumption by up to 80% compared to hydraulic systems.

Ultra-low carbon emissions for sustainable manufacturing.

Minimal maintenance requirements.

No continuous noise pollution—ideal for quieter production environments.

Wide Tooling Range: Supports thick turret tooling for versatile punching applications.

Fastest Punch Press on the Market: Delivers unmatched speed and efficiency.

Automation Module Options:

Vertical loading

Horizontal loading

Gantry-style robotic handling

Multiple Upgrade Options Available: Expandable to meet diverse production needs.

Automatic Flat Bar Deburring: Designed specifically for efficient and consistent deburring of flat steel bars.

Servo Motor Drive: Ensures precise control and stable performance.

Consistent Quality: Delivers uniform edge finishing across all processed parts.

High Operational Safety: Engineered with operator safety as a priority.

Dust-Free End Milling: End-face finishing is performed via milling, eliminating dust and minimizing contamination.

Seamless Integration: Can be connected to the VaskiPUNCH system for a fully automated punching, cutting, and deburring production line.

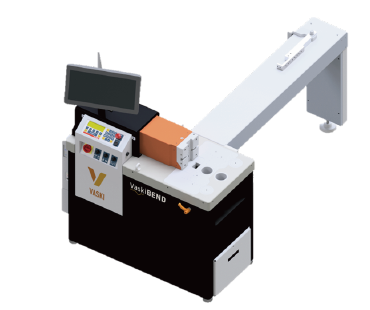

Monoblock Frame: Provides maximum bending rigidity for stable and consistent performance.

Bending Force: Available in 400 kN and 800 kN configurations.

Drive System: Hydraulic-powered bending system ensures reliable force delivery.

Backgauge System: Electrically driven, with positioning lengths of 1250 mm, 2000 mm, and 3000 mm.

Tool Change System: Manual tool exchange for flexible setup.

Bending Accuracy: Angular precision up to ±0.3°.

Maximum Forming Capacity: Rated at 1 (specify unit if needed, e.g., mm or ton).

Clamping System:

4-point clamping system with maximum tool height of H.350 mm.

6-point clamping system with maximum tool height of H.350 mm.

Stroke Range:

Prodigy 400: 3–245 mm.

Prodigy 800: 3–345 mm.

The ES Series press brake utilizes full electric servo control, offering eco-friendly operation and optimized performance for low-tonnage, high-precision bending applications.

Servo Electro-Hydraulic Technology: A servo motor drives the hydraulic pump, delivering precise oil flow control. With a motor power of 6.5 kW, the system operates only during active bending, ensuring efficient energy use.

Fully Closed-Loop Control: Enables rapid response and accurate positioning for consistent forming results.

Exceptional Bending Accuracy: Achieves angular precision up to ±0.5°.

High-Speed Operation: Fast approach/retract speeds up to 200 mm/s and bending speed of 15 mm/s enhance productivity.

Robust Pressing Capability: Sufficient force and pressure retention to handle thick plates and high-strength materials such as stainless steel.

Energy-Saving Design: Reduces power consumption by over 40% compared to traditional hydraulic systems.

Low Noise Emission: Operates below 60 dB, contributing to a quieter and safer working environment.

The AG Series press brake adopts a conventional downward-acting hydraulic control system, offering simple operation and reliable performance for precision sheet metal fabrication.

The machine frame features an open height of 400 mm—among the largest in its class—providing superior clearance for part positioning and expanding the range of applicable workpieces.

High bending accuracy with angular precision up to ±0.5° ensures consistent forming quality.

Fast approach and retract speeds exceeding 58 mm/s, with a bending speed of 12 mm/s, deliver efficient cycle times.

Equipped with sufficient pressing and holding force to handle high-strength materials such as thick plate and stainless steel.

The lower beam’s starting position can be freely set, enabling rapid setup and bending operations.

The hydraulic cylinder engages only during bending; descent relies on gravity return, offering improved energy efficiency over traditional upward-acting systems.

Downward motion during bending allows operators to intuitively monitor machine status, enhancing operational safety.

• Industry 4.0 architecture enables seamless system upgrades, high-speed operation, consistent part forming, low power consumption, and simplified daily maintenance with reduced costs.

• High level of automation with intuitive operation interface, minimizing skill requirements for operators.

• No tooling required — complex geometries (including upward/downward bends, right angles, and non-right angles) can be freely designed and produced on demand.

• The bending center features extensive hardware and software interfaces, compatible with various loading and unloading configurations.

• The control system supports true multi-axis concurrent motion, ensuring smooth bending actions and high mechanical coordination; the user interface is friendly and easy to understand, with flexible programming capabilities.

• Equipped with off-center load detection, adaptive load compensation, and thick plate sensing, the system effectively protects both the machine and the workpiece, reducing material waste.

• A cloud-based operation and maintenance management system enables real-time monitoring of machine performance and status.

• For non-standard workpieces, the system allows selection of different positioning references based on part geometry, ensuring that any shearing deviation is absorbed at the first bending edge — guaranteeing final dimensional accuracy.

• Wide material compatibility, including stainless steel, carbon steel, copper, and aluminum sheets.

• Fast and intuitive programming, enabling simultaneous multi-axis coordination for complex bending operations.

• Universal bending tooling allows multi-edge, multi-tool forming of workpieces, achieving intricate profiles with high flexibility.

• Significantly enhanced bending efficiency, precision, and consistency, ensuring reliable repeatability across production batches.

• Compared to conventional press brakes, the multi-edge bending center delivers a 3–5× increase in overall productivity and 50% reduction in energy consumption, making it an ideal solution for high-efficiency, stable output of box-type components and large-format sheet metal parts.

Ultra High Speed High Precision Press

Ultra High Speed High Precision Press

Double Link Motion Precision Stamping Press

Double Link Motion Precision Stamping Press