MU-V Series – Redefining the Standards of 5-Axis Machining

Models: MU-5000V / MU-6300V / MU-8000VBreakthrough in spatial accuracy

Equipped with a high-rigidity trunnion table, supporting high-precision 5-axis machining

A 5-axis machining center optimized for cutting performance

Pushing the limits of 5-axis machining

Achieves high-efficiency machining with astonishing cutting capability

Turning capability comparable to a lathe, enabling process integration

Designed for excellent visibility and operability in 5-axis machining

Easy access to the machining area

Ensures a large machining envelope

Tool change possible with the trunnion in indexing position

Models: VTM-65 / VTM-100 / VTM-200

VTR‑160A / VTR‑350A

High rigidity and stable precision

Process integration for large‑diameter, heavy workpieces

LB2000 EXⅡ / LB3000 EXⅡ / LB4000 EXⅡ / LB2500 EXⅡ

A best‑selling series that delivers higher productivity in precision component machining

Features a unique slant‑box bed construction for superior rigidity and structural integrity

Incorporates the Thermo‑Friendly Concept for unprecedented dimensional stability

Advanced machining capability ensures improved production efficiency

Y‑axis functionality enables process integration, allowing irregular workpieces to be fully machined in a single setup

Available in a wide range of models to support diverse production requirements

The standard in compact single‑turret CNC lathes

Standard chuck size (inch): 8

Maximum turning diameter (mm): Ø280

Maximum turning length (mm): 330

Spindle speed (min⁻¹): 3,000

Turret type: V8

Spindle motor power (kW): 7.5 / 5.5 (15 min / continuous)

Machine dimensions (W × D × H, mm): 1,595 × 1,589 × 1,590

CNC control: FANUC only

HL‑20 / HL‑35

An expert in high rigidity, high precision, and high efficiency machining.

LT2000EX / LT3000EX

Equipped with left and right opposed spindles and upper/lower turrets, enabling complete machining on a single machine

Achieves an ideal balance of first and second operations

A comprehensive model lineup supports an excellent production system

Options such as triple‑turret simultaneous machining and synchronous Y‑axis upper/lower machining allow configurations tailored to production requirements

Further enhances productivity and process integration

LU3000 EX / LU4000 EX

Delivers flexible 4‑axis machining for diverse applications

Simultaneous 4‑axis machining with upper and lower turrets significantly reduces cycle time

Steady rest support ensures vibration‑free cutting

Balanced cutting capability enables high‑efficiency machining of long workpieces

Achieves powerful cutting and high‑speed operation, shortening cycle time

Provides high machining capacity (tested values) even under heavy synchronous cutting loads

A comprehensive model lineup supports an excellent production system

Y‑axis functionality enables process integration, allowing complex workpieces to be fully machined in a single setup

Large machining capacity: Upper Ø900 mm, Lower Ø670 mm; maximum swing diameter Ø1,200 mm

In addition to a wide machining range, diverse specifications meet various application requirements

High‑power cutting capability enhances productivity

Heavy‑duty cutting performance: 10 mm² (1,500 cm³/min) with workpiece material S45C

Upper turret (special specification) with powerful milling capability

Y‑axis functionality enables process integration for complex geometries

Equipped with dual turrets, achieving machining innovation

LU35Ⅱ / LU45Ⅱ

High‑efficiency 4‑axis CNC lathe engineered for medium‑ to large‑size component machining.

Compact Twin‑Turret CNC Lathe Designed to significantly enhance productivity in mass‑production machining.

Standard chuck size (inch): 8

Maximum turning diameter (mm): Ø160

Maximum turning length (mm): 480 / 550 / 1,000

Spindle speed (min⁻¹): 4,000

Turret type: Upper / Lower: V6

Spindle motor power (kW): 11 / 7.5 (30 min / continuous)

Machine dimensions (W × D × H, mm):

2,440 × 1,980 × 2,054

3,235 × 2,282 × 2,247

CNC control: OSP / FANUC

Delivers high productivity in machining ring‑shaped components.

Standard chuck size (inch): 8

Maximum turning diameter (mm): Ø200 (machine capability)

Maximum turning length (mm): 100

Spindle speed (min⁻¹): 4,000

Turret type: Left / Right: V8

Spindle motor power (kW): 15 / 11 (30 min / continuous)

Machine dimensions (W × D × H, mm): 1,550 × 1,935 × 2,015

CNC control: FANUC only

The 2SP Series, renowned for its space‑saving design and high‑efficiency performance.

Incorporating the Thermo‑Friendly Concept, this machine delivers stable machining accuracy.

Standard configuration includes a gantry loader to shorten cycle time

Standard chuck size (inch): 6

Maximum turning diameter (mm): 150 (machine capability: 220)

Maximum turning length (mm): 80 (machine capability: 150)

Spindle speed (min⁻¹): 4,500

Turret type: Left / Right: V12

Spindle motor power (kW): 11 / 7.5 (30 min / continuous) × 2

Machine dimensions (W × D × H, mm): 1,850 × 2,150 (machine only) × 2,648 (including status indicator light)

Expansion specification: M

CNC control: OSP / FANUC

Combining high‑speed loading with powerful milling capability, this machine significantly reduces machining time.

Machine construction designed for both high‑speed loading and heavy‑duty cutting performance

Greatly reinforced spindle improves productivity

High‑speed gantry system shortens production cycle time

Ensures long‑duration, high‑precision stable machining

Cutting‑optimized structural bed achieves superior machining quality

Maximum workpiece diameter: Ø250 mm, ideally suited for mass production of components

Maximizes the advantages of a vertical CNC lathe, delivering outstanding area productivity and high overall efficiency.

Ensures stable machining even for large‑diameter thin‑walled parts or unbalanced, irregular‑shaped workpieces that are difficult to clamp

A large machining area accommodates a wide range of applications

A high‑rigidity machine structure enables powerful and high‑precision cutting

Powerful milling capability allows effective process integration

Supports

Vertical CNC Lathe V40 / 2SP‑V40 Vertical 2‑axis CNC Lathe V100R

Designed to improve productivity in machining medium‑ to large‑scale flange‑type workpieces

Ensures stable machining of thin‑walled and irregular‑shaped components

Achieves stable cutting through workpiece self‑weight clamping and close contact with fixture surfaces

Equipped with a wide‑range rated output spindle motor

Flange‑type spindle headstock minimizes the effects of thermal displacement and vibration

Enables process integration, reducing semi‑finished parts to zero

Provides dual‑purpose machining capability for high production efficiency

With a compact machine body, this CNC lathe delivers enhanced machining capability and stable high‑precision performance.

Standard chuck size (inch): 8 / 10

Maximum turning diameter (mm): Ø250

Maximum turning length (height, mm): 350

Spindle speed (min⁻¹): 6,000

Turret type: V12

Spindle motor power (kW): 15 / 11 (short‑time / continuous)

Machine dimensions (W × D × H, mm): 950 × 2,600 × 2,445

Expansion specification: M

CNC control:

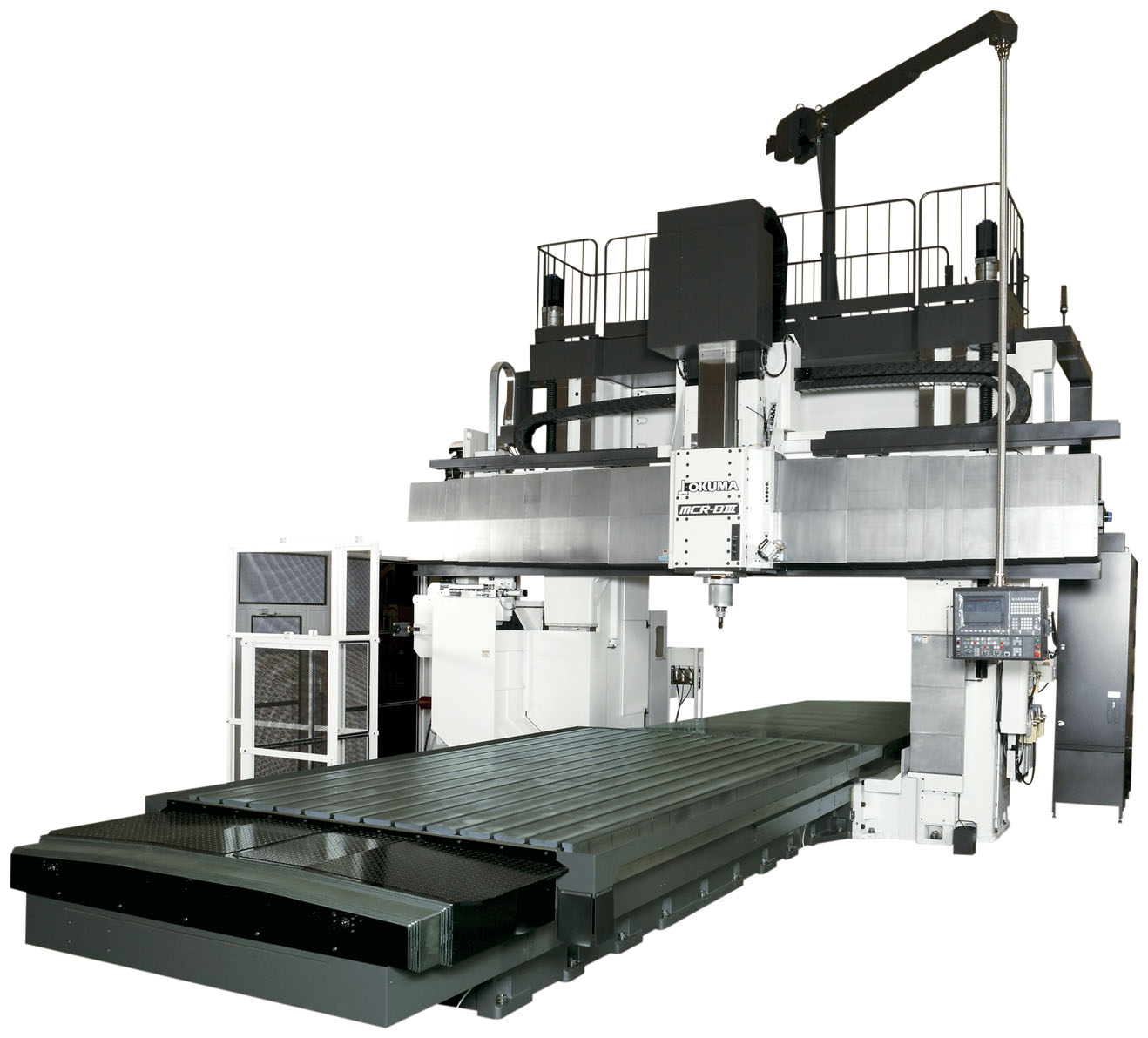

MB‑46VA / MB‑56VA / MB‑66VA

Achieves higher‑than‑expected productivity with a high‑rigidity machine structure:

Developed using 3D‑CAD design and FEM (Finite Element Method) analysis for optimized rigidity

Employs a proven high‑rigidity gantry‑type structure

Feed axis bearing housings are integrated with the machine frame for enhanced stability

Delivers powerful spindle cutting capability for heavy‑duty machining:

504 cm³/min (face milling)

672 cm³/min (side milling)

Enhances component machining quality with:

High‑precision machining

Superior positioning accuracy

Thermo‑Friendly Concept for stable accuracy under thermal variations

Achieves both large Y‑axis travel and excellent operability, making it ideal for machining medium‑ to large‑scale components.

Superior accessibility to the table and spindle ensures outstanding ease of operation

Capable of high‑efficiency machining of molds and semiconductor manufacturing components

From general machine parts to molds and aluminum components, a comprehensive spindle lineup meets diverse machining requirements

Supports extended unmanned operation

Chip management performance enables easy removal of large volumes of aluminum chips

Incorporates the unique Thermo‑Friendly Concept, designed to “accept temperature changes” and maintain stable accuracy

Achieves superior surface quality in mold machining with Hyper‑Surface (special specification)

Equipped with a two‑station rotary APC (Automatic Pallet Changer), this CNC Vertical Machining Center is well‑suited for integration into automated production lines.

Table size (pallet size, mm): 760 × 460

Spindle speed (min⁻¹): 8,000 / 6,000

Tool magazine capacity: 20 tools

Spindle motor power (kW): 11 / 7.5 (10 min / continuous)

Machine dimensions (W × D × H, mm):

Significantly enhances productivity in mold and high‑precision component machining, while achieving a higher level of surface quality.

A CNC Vertical Machining Center designed specifically for precision components and mold machining.

Table size (mm): 760 × 460

Spindle speed (min⁻¹): 20,000

Tool magazine capacity: 20 tools

Spindle motor power (kW): 15/11 (10 min/continuous)

Machine dimensions (W × D × H, mm): 2,224 × 2,734 × 2,630※

By adopting hybrid guideways combining box‑way sliding and linear rolling elements, the machine achieves the best of both worlds: high‑speed machining and powerful heavy‑duty cutting.

Models: MA‑550VB / MA‑650VB

A machine tool designed for automated production lines, combining space‑saving design with a large machining area.

X, Y, Z axes with box‑way slide guides

VAC built‑in motor spindle

Two‑face contact spindle taper for superior cutting stability

Reduces both non‑cutting time and cutting time, achieving high production efficiency

The MILLAC VII Series is designed for heavy‑duty cutting of medium‑ to large‑scale components.

Featuring a high‑rigidity structure that enables reliable high‑speed cutting, the machine base and column are reinforced with ribs positioned at optimized locations to suppress high‑frequency vibration and torsional stress during powerful cutting operations.

All axes adopt traditional box‑way slide guides, ensuring long‑term high accuracy and rigidity.

MILLAC 468VⅡ

Cutting capacity: 360 cm³/min

Spindle: No.50 taper, 6,000 min⁻¹, 18.5 kW built‑in motor

MILLAC 561VⅡ

Cutting capacity: 588 cm³/min

Spindle: No.50 taper, 10,000 min⁻¹, 22 kW built‑in motor

MILLAC 761VⅡ / MILLAC 852VⅡ

Cutting capacity: 540 cm³/min

Spindle: No.50 taper, 4,000 min⁻¹, 18.5 kW two‑stage gear‑driven spindle head

MILLAC 1052VⅡ

Cutting capacity: 756 cm³/min

Spindle: No.50 taper, 4,000 min⁻¹, 22 kW two‑stage gear‑driven spindle head

With a powerful 10,000 min⁻¹ spindle (special specification), the machine enhances machining capability and supports diverse requirements ranging from heavy‑duty cutting to high‑feed machining.

By expanding the machining range, it significantly improves area productivity.

Incorporates chip management measures designed to maximize machine uptime.

A maintenance‑free coolant tank ensures stable operation.

Compatible with automation solutions to further increase productivity.

With a new spindle lineup, the machine accommodates a wider range of machining applications.

Powerful new spindle: 10,000 min⁻¹, No.50 taper (special specification)

Supports diverse requirements from heavy‑duty cutting to high‑feed machining

Extended travels make it more suitable for large‑scale workpiece machining

Expanded machining range significantly improves area productivity

Ensures outstanding dimensional stability even during long‑duration machining of large workpieces

Incorporates the unique Thermo‑Friendly Concept, designed to “accept temperature changes” and maintain stable accuracy.

Reduces non‑cutting time, enhancing overall productivity

Chip management measures maximize machine uptime

Maintenance‑free coolant tank

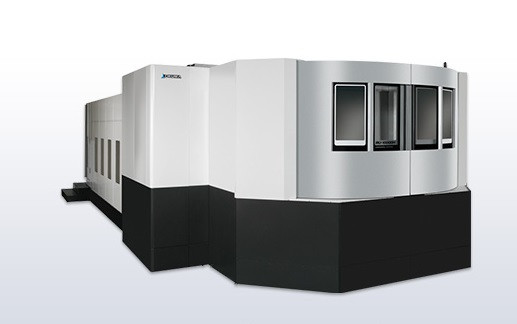

Achieves high productivity across a wide range of manufacturing fields.

From heavy‑duty cutting to precision machining, its performance exceeds expectations, making it a flagship machining center.

Pallet size (mm): 500 × 500

Maximum workpiece size (mm): Ø800 × 1,000

Spindle speed (min⁻¹): 6,000

Tool magazine capacity: 40 tools

Spindle motor power (kW): 30/22 (10 min/continuous)

Machine dimensions (W × D × H, mm): 3,110 × 5,971 × 3,174

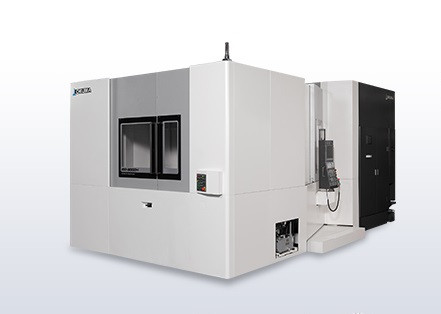

By adopting the Thermo‑Friendly Concept, the machine achieves stable machining accuracy and high reliability, thereby further enhancing productivity.

Pallet size (mm): 400 × 400

Maximum workpiece size (mm): Ø600 × 710

Spindle speed (min⁻¹): 8,000

Tool magazine capacity: 30 tools

Spindle motor power (kW): 15/11 (10 min/continuous)

Machine dimensions (W × D × H, mm): 2,414 × 4,532 × 2,759

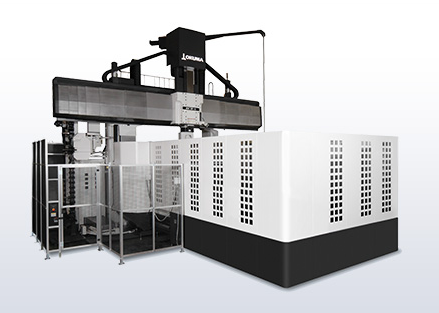

Powerful performance and high‑speed operation deliver enhanced productivity in large‑scale workpiece machining.

Pallet size (mm): 1,250 × 1,250

Maximum workpiece size (mm): Ø2,000 × 1,600

Spindle speed (min⁻¹): 6,000

Tool magazine capacity: 81 tools

Spindle motor power (kW): 45/37 (20 min/continuous)

Machine dimensions (W × D × H, mm): 6,880 × 12,512 × 3,781

High‑speed machining of aluminum mass‑production components.

By utilizing high‑acceleration/deceleration axis feed systems, positioning time is significantly reduced. Combined with high‑speed B‑axis rotation, high‑speed ATC (Automatic Tool Changer), and high‑speed drilling capability, the machine ranks among the world’s mainstream machining centers, achieving a substantial reduction in cycle time.

Reduced positioning time

Cycle‑time reduction functions

Shortened table indexing time

Shortened ATC time

Equipped with a lineup of high‑rigidity, high‑torque spindles.

Incorporates chip management measures designed to maximize machine uptime.

From high‑volume part production to high‑value large‑scale component machining, the MB‑H Series High‑Speed CNC Horizontal Machining Centers deliver outstanding performance.

Models available: MB‑4000H / MB‑8000H / MB‑10000H

With a compact machine design, the MILLAC 44HⅡ / MILLAC 55HⅡ achieves a significant reduction in machining time for small components while greatly improving production efficiency.

A space‑saving, cost‑effective universal machine.

Equipped with a 2‑station AAC (Automatic Attachment Changer) mounted inside the right column, significantly reducing overall machine width.

Features 5C components designed for general 5‑face machining applications.

Offers excellent ease of installation and compact footprint, making it suitable for diverse machining environments, including industrial machinery and conveyor equipment component manufacturing.

A compact, high‑value machine tool that integrates technical excellence with space‑efficient design.

From general part machining to high‑precision operations, this machine delivers high productivity across a wide range of machining applications.

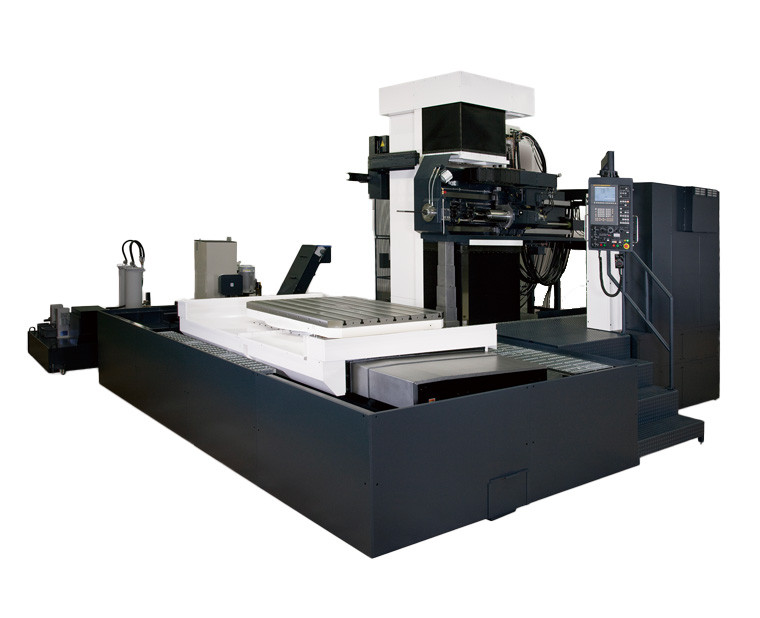

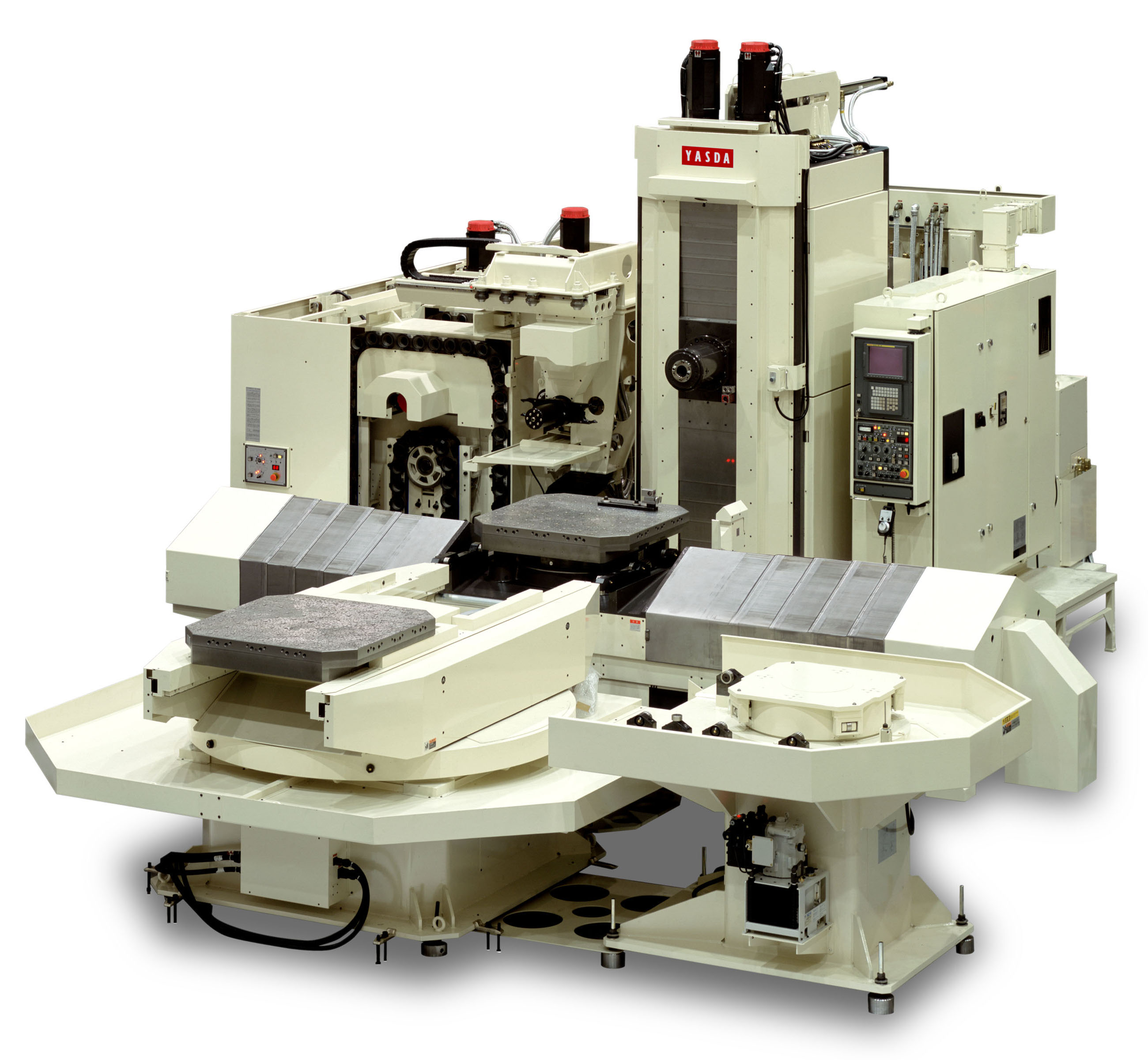

A versatile machining center capable of handling a wide range of applications, from high‑precision machining to heavy‑duty cutting.

Utilizes reference gauges and contact probes for automatic measurement with simple operation. Anyone can easily calibrate the machine’s accuracy. (Contact probe and reference gauge available as special specifications.)

Controls thermal displacement in large machine tools. Ensures dimensional stability even under conditions where thermal displacement is difficult to suppress, such as:

Ambient temperature fluctuations

Machine startup or restart of machining operations

Standard spindle equipped with a high‑torque, high‑power built‑in motor

Compatible with over 100 types of diverse spindle heads

Delivers overwhelming cutting capability, ideally suited for large‑scale component machining in heavy industries.

A single machine meets the dual requirements of efficient rough machining and high‑precision finishing for large workpieces in heavy‑duty applications.

Employs a high‑rigidity sliding ram with a cross‑section of 420 × 425 mm, providing the strength required for powerful cutting.

Offers a maximum spindle torque of 2,025 N·m.

With a wider gantry span and extended longitudinal travel, the machine easily accommodates larger and taller workpieces

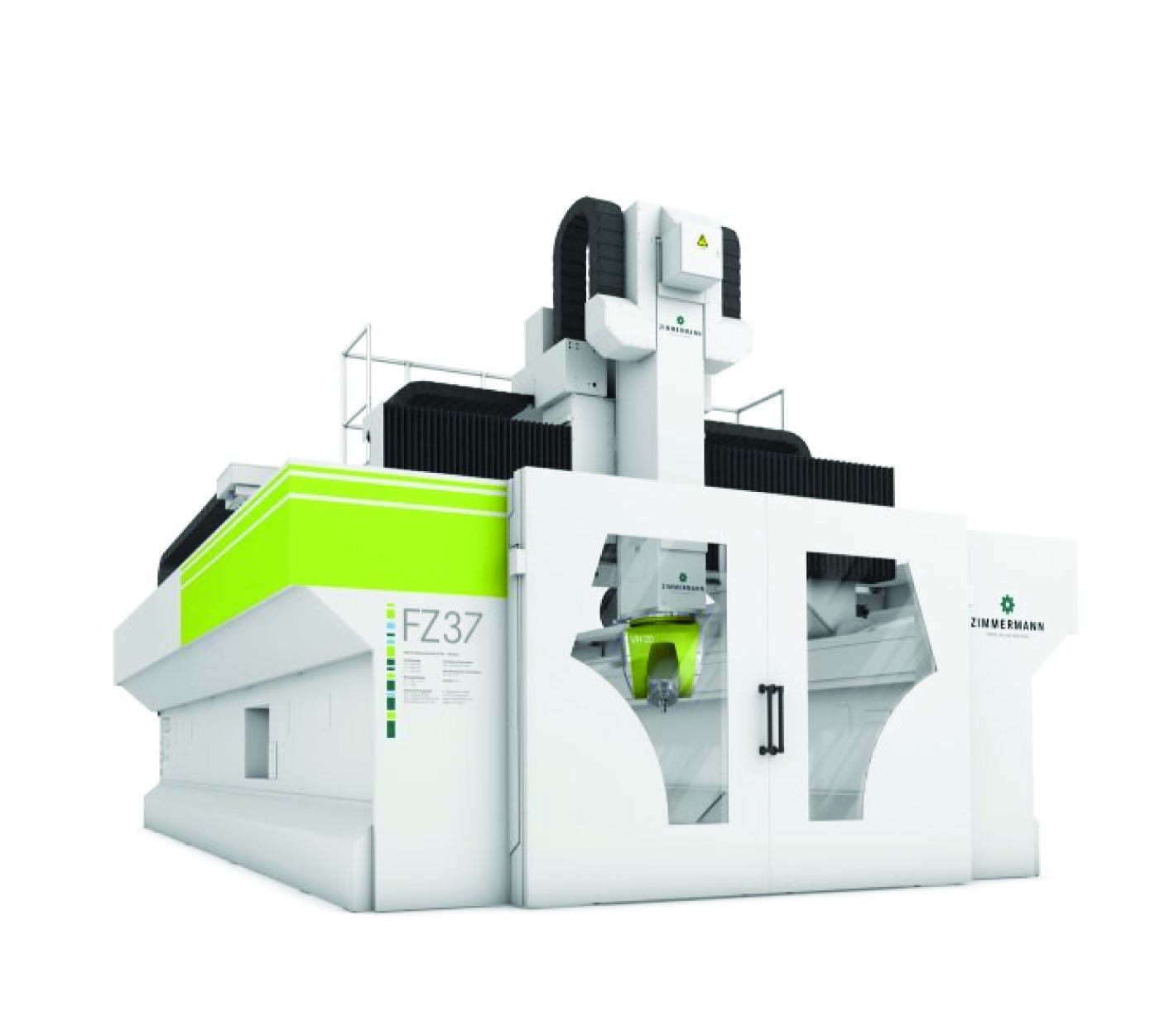

A high‑speed, high‑quality machining center that drives innovation in stamping die manufacturing.

Significantly reduces the time required for post‑process polishing and upper/lower die matching, thereby greatly shortening die manufacturing lead time.

Features a machine structure designed for continuous high‑speed cutting feed and a 20,000 min⁻¹ high‑speed spindle head, while maintaining excellent form accuracy and superior surface quality.

Standard specifications enable high‑grade die surface finishing.

Delivers quiet, high‑speed, and powerful cutting performance.

Equipped with a direct‑drive, gearless spindle, eliminating intermittent gear noise during cutting.

The low‑noise operation improves the working environment.

Reduced cutting vibration minimizes insert breakage and wear, thereby extending tool life.

Ensures high reliability, with a spindle cooling system provided as standard, maintaining stable accuracy.

Built with a gantry‑type structure that guarantees high precision and rigidity.

Incorporates an NC‑ATC (Numerical Control Automatic Tool Changer) for high‑speed tool change capability.

Optional Hyper‑Surface specification enables high‑speed, high‑precision, and high‑quality machining of complex 3D geometries.

Featuring a high‑rigidity, high‑precision machine structure.

The spindle head adopts a sliding‑ram design with a large cross‑section of 350 × 350 mm, providing the rigidity required for heavy‑duty cutting.

Equipped with dual ball screws on the Z‑axis plus an absolute linear scale (standard).

Delivers powerful, high‑precision, and high‑speed machining through a hybrid guideway system combining sliding and rolling elements.

Rapid traverse (X/Y axes): 20 m/min

Cutting feed rate: 10 m/min

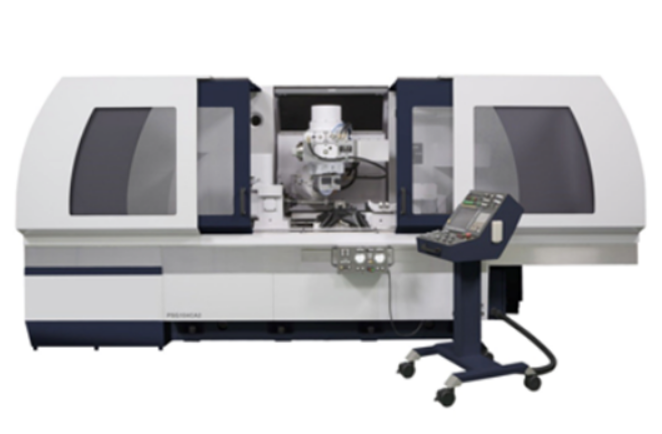

GP/GA14/15W

GP/GA25/26W

GPW Series – Parallel Wheelhead

GAW Series – Angular Wheelhead

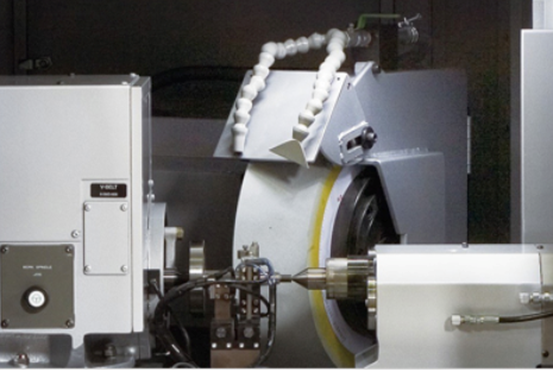

Pushing the limits of manufacturing, these machines combine the dual advantages of high‑precision grinding and high‑efficiency operation.

Featuring a transverse wheelhead configuration for space‑saving design.

Engineered with exceptional convenience and automation‑ready design.

Utilizes a hydrodynamic bearing spindle structure, enabling both heavy‑duty grinding and high‑precision machining, while reducing cycle times.

Incorporates wide V‑flat guideways to maintain high machining efficiency.

Equipped with top‑class high‑speed axis feed systems, further shortening machining time.

Equipped with a grinding spindle designed for both heavy‑duty stock removal and high‑precision machining.

Capable of handling long workpieces up to 1,500 mm in length.

Designed to meet the demands of high‑cycle production lines.

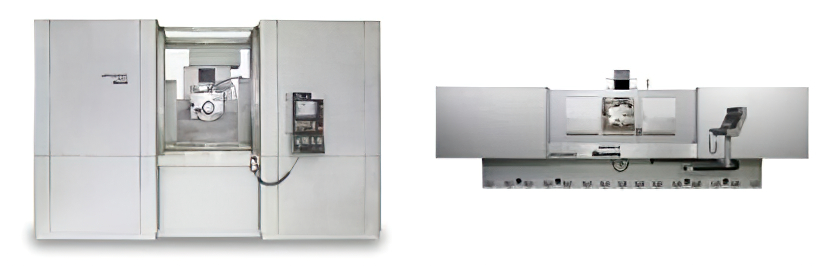

A compact, high‑speed CNC internal grinding machine.

Workpiece capacity (weight × length): 100 kg × 150 mm

Swing diameter inside chuck guard: Ø350 mm

Grinding diameter range: Ø3 – Ø150 mm

Maximum grinding depth: 150 mm

Grinding spindle motor power: 5.5 kW

Machine dimensions (W × D × H):

Delivers stable, high‑precision machining.

Incorporates the traditional OKUMA 5‑face hydrostatic guideway design.

Both the cross slide and work table are supported by an oil‑film suspension, ensuring excellent dynamic responsiveness.

The sliding carriage is supported on five faces at both upper and lower sections, providing superior rigidity.

A wide spacing between adjacent guideway surfaces enhances vibration damping while achieving high speed and high rigidity.

The fully enclosed structure with upper and lower support improves accuracy and extends the durability of the guideways.

Ideally suited for precision grinding of mold contours.

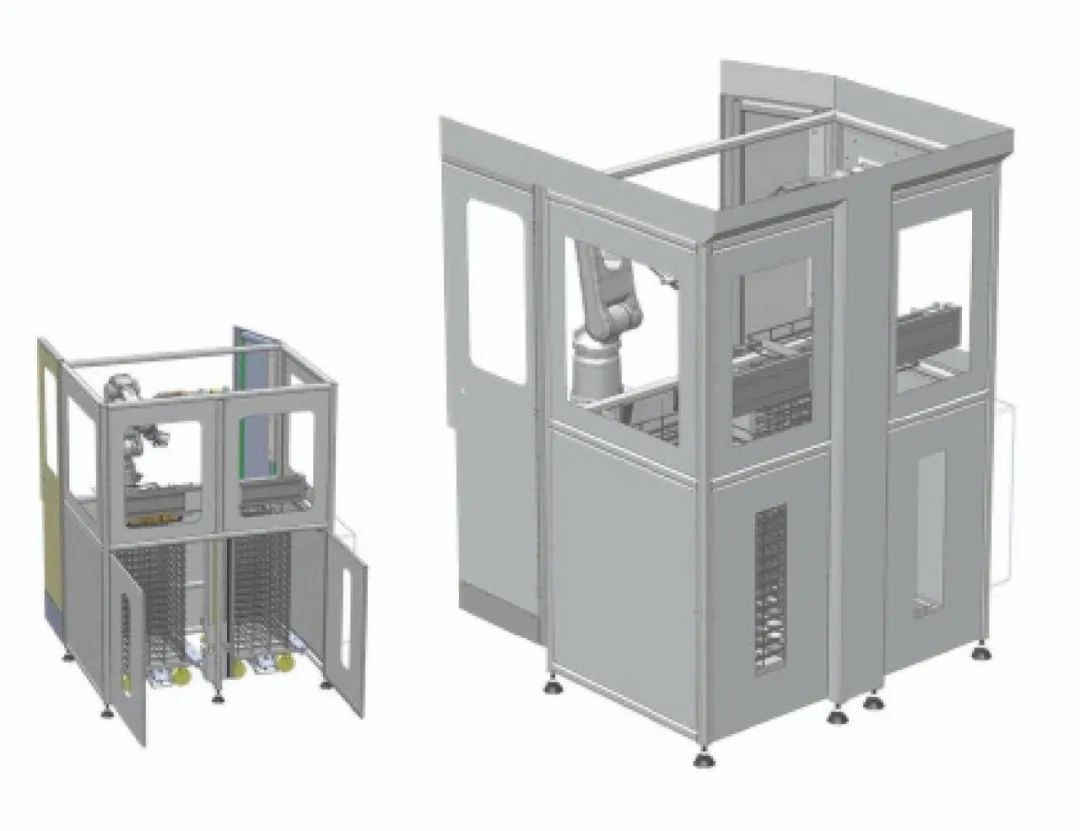

A simple robotic package that can be installed and commissioned in as little as one day.

Robots can be operated as easily as conventional machine tools, requiring no specialized robotics knowledge or system integrators.

Developed specifically for machine tool operators, the “ROID Navi” system automatically generates optimized robotic motion paths.

Anyone can easily operate both the machine tool and the robot.

Through the CNC unit, the robot can be controlled with the same operational feel as the machine tool, ensuring intuitive usability.

For added convenience, the pulse handle of the machine tool allows precise manual fine‑tuning of the robot’s position.

Comprising a hyper‑integrated built‑in robot located inside the machining chamber of an intelligent machine tool, together with an innovative robotic operating system that offers the same operational feel as a conventional machine tool, this is a next‑generation robotic system that delivers true automation and productivity innovation.

Key innovations enabled by the built‑in robot include:

Simple operation

Acting as a skilled technician

Transforming the way work is performed

Featuring a high‑power, compact turret design.

A machine tool that integrates turning and machining center capabilities, consolidating the full functionality of an NC lathe and machining center production line into a single unit.

Delivers enhanced machining efficiency through reliable accuracy and powerful cutting performance.

With a wide range of application programs, the machine enables complete machining of large‑diameter, long‑size workpieces on a single platform.

Delivers productivity surpassing conventional large machine tools and machining centers.

Equipped with a CNC control system developed in‑house by the machine tool manufacturer, ensuring exceptional ease of operation.

Achieves shorter cycle times through powerful cutting performance.

Its high‑rigidity structure demonstrates outstanding capability even in the machining of difficult‑to‑cut materials.

Provides precision levels beyond the conventional expectations of large machine tools.

The most advanced CNC machine tool for aluminum alloy wheel machining, designed for large‑size wheels up to 24.5 inches.

Capable of machining aluminum alloy wheels ranging from 15 to 24.5 inches.

Engineered with high precision, superior rigidity, stable workholding, easy loading/unloading, and complete chip management.

Equipped with a high‑speed spindle and rapid feed rates for maximum productivity.

Features left/right V6‑type tool turrets, with an optional Automatic Chuck Change (ACC) system.

The latest global CNC lathe series from OKUMA — GENOS L Series

A high‑value compact multi‑function machine, designed with a simplified structure that emphasizes high machining quality and ease of operation. With a wide range of specifications, the GENOS L Series is capable of handling everything from chucked workpieces to complex bar‑stock components.

The GENOS L Series is a machine tool engineered to meet every customer requirement.

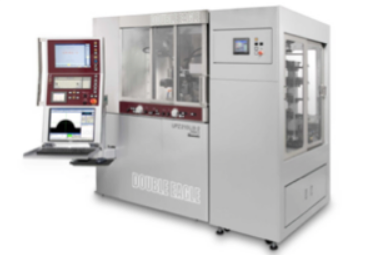

With the new COMPETITION Series, OGISO has further advanced its technology, building upon the proven success of the Gantry Eagle Series. Two years after integrating the POWERSPARK finishing generator into the flagship G5 PRECISION EDM machine, the COMPETITION Series now adopts the same innovative generator together with the all‑new PowerSpark ONE controller, enabling a wider customer base to benefit from cost‑efficient, next‑generation EDM technology.

In combination with the new PowerSpark EDITOR offline programming system, customers gain access to our leading high‑performance graphite machining technology. To meet the stringent requirements of users who prefer not to work with graphite, or for specific applications where copper electrodes continue to offer advantages, we have comprehensively upgraded our copper machining technology.

The new COMPETITION Series will be available in two machine sizes: G50 COMPETITION and G80 COMPETITION.

With the new COMPETITION Series, OGISO has further advanced its technology, building upon the long‑standing success of the Gantry Eagle Series. Two years after introducing the POWERSPARK finishing generator into the flagship G5 PRECISION EDM machine, the COMPETITION Series now incorporates the same innovative generator together with the all‑new PowerSpark ONE controller, enabling a broader customer base to benefit from cost‑efficient next‑generation EDM technology.

When combined with the new PowerSpark EDITOR offline programming system, customers gain access to our leading high‑performance graphite machining technology. To meet the stringent requirements of users who prefer not to work with graphite, or for specific applications where copper electrodes still offer advantages, we have comprehensively upgraded our copper machining technology.

The new COMPETITION Series will be available in two machine sizes: G50 COMPETITION and G80 COMPETITION.

The GANTRY EAGLE 400 EDM machining center sets a new benchmark for the precision mold manufacturing industry, providing a solid response to its ever‑increasing demands. Its gantry‑type construction ensures maximum accuracy, superior cost‑efficiency, and sustained synergy between high‑speed cutting and die‑sinking EDM design, making this model a truly distinctive highlight in the market.

Entry‑level automation in EDM machining

A new high‑end die‑sinking EDM solution for micro‑scale and ultra‑precision applications

A forward‑looking machine tool concept, designed for easy accessibility and intuitive operation

Good products are continuously improved. Our proven gantry-type machine structure forms the foundation of the new GANTRY EAGLE series, delivering high dynamic performance to meet the demanding requirements of EAGLE POWERTEC advanced technology.

The GANTRY EAGLE 500 meets the highest standards of precision machining.

When machining complex geometries, it achieves outstanding surface quality.

The GANTRY EAGLE 800 represents the perfect combination of a large working envelope, compact footprint, and unprecedented machining capability. It is your guarantee for success in the marketplace, delivering a decisive advantage in the high‑performance machining of medium to large workpieces.

The potential of the GANTRY EAGLE 1200 is truly unique. Thanks to its high feed rates and the advanced EAGLE POWERJUMP discharge technology, this machine delivers exceptional power and performance when machining complex workpieces, while also ensuring efficient processing of large molds.

Offering a wide range of application possibilities, the GANTRY EAGLE 1200 combines high-speed capability with precision machining accuracy.

As an option, the GANTRY EAGLE 1200 is also available in the “Plus” enhanced version.

Work tank dimensions: 1,140 × 1,640 × 990 mm

Maximum dielectric fluid level height: 950 mm

Maximum distance from worktable to electrode holder: 400 / 1,100 mm

Axis travel (X / Y / Z): 880 × 1,360 × 700 mm

The new GANTRY EAGLE 1400 large-scale gantry EDM machine is designed to meet customer demands for machining larger workpieces with high-precision detail.

With its high feed rates enabled by EAGLE POWERJUMP discharge technology and the advanced EAGLE POWERTEC generator, the GANTRY EAGLE 1400 ensures high power output and maximum efficiency even when machining large molds and complex components.

As an option, the GANTRY EAGLE 1400 is also available in the “Plus” enhanced version.

Work tank dimensions: 1,510 × 2,590 × 1,015 mm

Maximum dielectric fluid level height: 975 mm

Maximum distance from worktable to electrode holder: 300 / 1,200 mm

Axis travel (X / Y / Z): 1,250 × 2,350 × 900 mm

With decades of experience in the manufacturing and application of large-scale EDM equipment, Ogisso has become a trusted partner for the mold-making industry. The GANTRY EAGLE 2000 represents our forward-looking and flexible solution for large-scale electrical discharge machining operations in tool and die manufacturing.

Large gantry-type EDM machine

Maximum axis travel with minimal floor space requirement

Oversized dielectric work tank for complete submersion machining

Rigid gantry machine structure

Automatic electrode exchange for electrode weights ranging from 1–100 kg

Through manufacturing process optimization and the integration of all operations, our proven automation solution — MultiChange Linear automation system — elevates your production efficiency to the highest level.

Thanks to its modular architecture, the advanced technology package can be flexibly expanded to connect additional machining centers and auxiliary equipment, while seamlessly integrating in‑process measurement and quality control functions into the production workflow.

System configuration examples:

EAGLE MultiCell

GANTRY EAGLE 400 / 500 / 800 / 1200

SPEED HAWK 550 / 650 / 750

Do your high-speed machining centers or EDM machines require not only automatic electrode exchange but also automatic workpiece handling—yet without the need for a full job management system? Then MultiChange light is the cost-efficient and technically sound solution.

Safe and reliable operation

Positioning with encoded programming

Designed for heavy payload transfer

Upgradeable to a full version with job management system and multi-machine integration

OPS-Ingersoll MultiChange easy provides the most cost-effective entry into high-speed machining automation. It can be specifically configured for electrode or workpiece machining according to your requirements.

Positioning with coded programming

Capable of transferring heavy payloads

User-friendly operation

Retrofit-ready, even for earlier Ogisso high-speed machining centers

Compact footprint for efficient shopfloor utilization

Fully Automatic Die & Mold Machining Center

The integration of high‑speed machining and EDM (Electrical Discharge Machining) technologies ensures exceptional possibilities, delivering significant advantages to your manufacturing process.

The fully automatic die & mold machining center achieves a level of productivity unattainable by two separate systems.

Modular upgrades available, up to a complete die & mold machining center configuration.

Multi‑machine connectivity supported.

Substantial cost savings and shortened production cycles.

High‑Speed Machining Center EAGLE V5

The newly launched HIGH SPEED EAGLE V5 model is designed for flexible machining of small to medium‑sized workpieces.

With its dynamic performance and fully enclosed construction, it is the ideal solution for automated machining of graphite electrodes and other dust‑generating materials.

It is also well suited for precision machining of rigid components.

Stacker Series – Duplex

Workpieces can be stacked on any type of pallet with a high degree of autonomy. Since no manual intervention is required, production time can be extended.

Pallets can enter the stacking axis directly via a rotary gate or optional light curtain, enabling rapid response to changing production requirements without waiting for an entire batch to be returned.

Equipped with a movable protective cover, the storage area remains sealed at all times, allowing stack replacement without interrupting the production process.

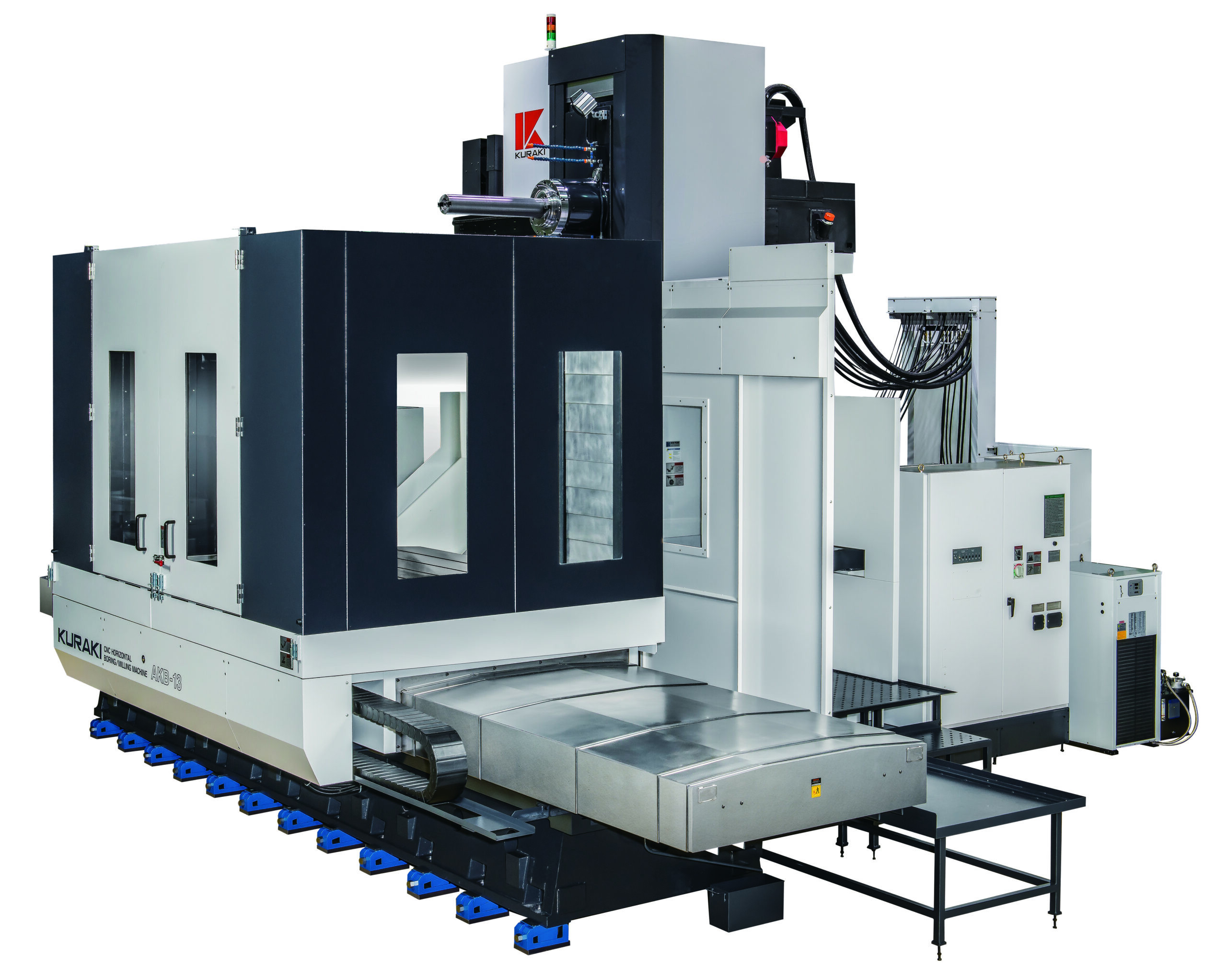

CNC Horizontal Boring and Milling Machining Center AKB‑11

Standard‑size machine tool.

Equipped with a gear‑driven spindle, standard speed of 3000 min⁻¹, motor power 26/22 kW, and maximum torque of 2154 N·m.

Column‑moving structure improves accessibility to the workpiece and enhances chip evacuation capability.

Travel ranges: X‑axis 2000 mm, Y‑axis 1500 mm, Z‑axis 1500 mm, W‑axis 500 mm, expanding the machining envelope for large workpieces.

Standard rotary table with a load capacity of 6500 kg.

CNC Horizontal Boring and Milling Machining Center KBM‑11SX/11S

The most space‑saving model in the horizontal boring and milling machining center series, combining excellent operability with high rigidity.

KURAKI horizontal boring and milling machine requires a minimum installation footprint of 4680 × 4600 mm, enabling efficient utilization of limited shop floor space.

High‑precision indexing operations allow rotary milling to be performed under standard specifications.

Spindle speed range: 5–3000 min⁻¹, spindle torque: 1581 N·m, delivering outstanding machining capability.

Offers the most powerful milling capacity in its class, achieving a material removal rate of 768 cm³/min.

CNC Horizontal Boring and Milling Machining Center KBM‑11EM

Exceptional rigidity and maneuverability; the high‑spec compact design enhances machining efficiency.

Industry‑leading boring spindle with a maximum speed of 5000 rpm, maintaining continuous high‑torque output even at low speed (5 rpm), enabling machining of large‑diameter boring operations.

Cutting feed rate of 12 m/min and rapid traverse rate of 24 m/min—double that of the standard model. All axes adopt hardened box ways, providing high rigidity and low vibration attenuation, fully supporting heavy‑duty cutting applications.

Designed for heavy workpieces; table load capacity up to 4 tons.

CNC Horizontal Boring and Milling Machining Center KBT‑11.A

Standard model in the 110 mm spindle diameter series, designed to meet a wide range of machining requirements.

Incorporates the fundamental functions of a horizontal boring and milling machining center, making it a highly versatile machine tool widely supported by users.

Y‑axis (spindle head vertical travel) stroke reaches 1500 mm, exceeding that of the KBM series, enabling machining of tall workpieces.

Three‑step spindle transmission provides high torque output, ensuring powerful heavy‑duty cutting performance.

CNC Horizontal Boring and Milling Machining Center KBT‑11W.A

Featuring a wide table travel range, suitable for machining a broad spectrum of workpieces.

Z‑axis (table left‑right travel) stroke reaches 1450 mm, providing ample capacity for diverse machining operations.

X‑axis (table front‑back travel) stroke extends to 2000 mm, exceeding that of the KBT‑11.A model and further expanding the machining envelope.

Three‑step spindle transmission delivers high torque output, enabling powerful heavy‑duty cutting performance.

CNC Horizontal Boring and Milling Machining Center KBT-11Z

A high‑rigidity machine tool designed to handle heavy‑duty workpieces with enhanced stability.

Column‑moving structure enables machining of large and heavy components while improving operator accessibility.

Equipped as standard with a spiral‑type chip conveyor arranged parallel to the X‑axis, ensuring efficient removal of chips and coolant management.

Y‑axis (spindle head vertical travel) stroke reaches 1800 mm, with a table size of 1400 × 1750 mm, exceeding that of the KBT‑11W.A model.

Three‑step spindle transmission provides high torque output, enabling powerful heavy‑duty cutting operations.

CNC Horizontal Boring and Milling Machining Center – KBT-11EZ

A high-speed, high-rigidity machining center further reinforced to handle heavy workpieces with superior performance.

Features a moving column design, enabling the machining of heavy components while improving workpiece accessibility.

Standard-equipped with a helical chip conveyor parallel to the X-axis, ensuring efficient chip removal and coolant management.

Provides extended travel and table capacity:

Y-axis (spindle head vertical travel): 1800 mm

Table size: 1400 × 1750 mm, larger than the KBT-11W.A model.

Delivers a spindle speed of 4500 min⁻¹, ranking among the premium class in the industry.

Ball screws adopt a center-cooling system, achieving rapid feed rates of 18 m/min and cutting feed rates of 12 m/min.

The spindle drive incorporates a 3-step gear transmission, providing high torque for powerful heavy-duty cutting operations.

CNC Horizontal Boring and Milling Machining Center – AKB-13

A standard high-power machine tool designed for heavy-duty applications.

Equipped with a gear-driven spindle at 3000 min⁻¹, delivering motor output of 30/22 kW and a maximum torque of 3452 Nm.

Features a moving column design, improving workpiece accessibility and chip disposal capability.

Provides extended travel ranges:

X-axis: 3000 mm

Y-axis: 2000 mm

Z-axis: 1600 mm

W-axis (spindle extension): 700 mm Expanding the machining envelope for large-scale workpieces.

Standard-equipped with a rotary table capable of supporting 12,000 kg load capacity.

CNC Horizontal Boring and Milling Machining Center – AKB-11 (6000 rpm) / AKB-13 (6000 rpm)

Equipped with a two-step gear-driven spindle delivering 6000 min⁻¹, with a long-nose spindle design that improves workpiece accessibility.

The 6000 min⁻¹ dual-gear spindle drive provides motor output of 37 kW (S3 25%) / 22 kW, achieving a maximum torque of 1158 Nm.

Features a moving column design, enhancing both workpiece accessibility and chip disposal capability.

Standard-equipped with a rotary table, ensuring versatile machining performance.

CNC Horizontal Boring and Milling Machining Center – KBT-13.A

In line with the trend toward large-scale workpieces, this model serves as the standard machine leading the horizontal boring and milling machining center series.

Achieves high rigidity through the use of large-diameter ball screws on all axes and an angular guideway structure, making it an outstanding machine not to be missed.

Features a moving column design, enabling the machining of heavy workpieces while improving workpiece accessibility.

Standard-equipped with a helical chip conveyor parallel to the X-axis, ensuring efficient handling of chips and cutting fluid.

The spindle drive incorporates a 3-step gear transmission, delivering high torque for powerful heavy-duty cutting operations.

CNC Horizontal Boring and Milling Machining Center – KBT-13E.A

Among boring and milling machines with a 130 mm spindle diameter, this model offers the highest spindle speed, enabling high-speed machining.

Delivers a premium spindle speed of 4000 min⁻¹.

Equipped with a 4-step gear-driven spindle and 45 kW (60 HP) high-power output, providing exceptional performance in heavy-duty cutting and large-diameter deep hole machining.

Capable of machining 170 mm diameter holes with ease under cutting conditions of 0.2 mm/rev feed rate.

In milling operations, achieves a maximum material removal rate of 1544 cm³/min, ensuring outstanding productivity.

CNC Horizontal Boring and Milling Machining Center – KBT-13B.A

Provides a maximum workpiece load capacity of 20,000 kg, meeting the demands of large-scale components. A popular model trusted by many repeat customers.

Compared with conventional models KBT-13.A / KBT-13E.A, the maximum workpiece load capacity has been increased from 12,000 kg to 20,000 kg.

Offers extended travel range:

Z-axis (column cross travel): 1600 mm, expanding the machining envelope for large workpieces.

The spindle drive features a 3-step gear transmission, delivering high torque for powerful heavy-duty cutting operations.

CNC Horizontal Boring and Milling Machining Center – KBT-13EB.A

A high-quality, popular model that combines a spindle speed of 4000 min⁻¹ with a maximum workpiece load capacity of 20,000 kg.

Compared with conventional models KBT-13.A / KBT-13E.A, the maximum workpiece load capacity has been increased from 12,000 kg to 20,000 kg.

Provides extended travel range:

Z-axis (column cross travel): 1600 mm, expanding the machining envelope for large-scale workpieces.

The spindle drive features a 4-step gear transmission, delivering high torque for powerful heavy-duty cutting operations.

CNC Horizontal Boring and Milling Machining Center – KBT-13EM.A

Powered by a large-diameter heavy-duty spindle and a high-rigidity machine bed, delivering outstanding machining performance. Within its class, it is a super high-power model that greatly enhances mold machining efficiency.

With the advantages of high torque, high power, and high rigidity, it significantly improves efficiency in deep hole machining as well as roughing and semi-finishing of difficult-to-cut materials.

Offers high-quality spindle speed of 4000 min⁻¹, among the best in its class.

With rigidity far superior to other machines of similar size, it fully meets the requirements for efficient machining of difficult-to-cut materials and large-scale mold processing

CNC Horizontal Boring and Milling Machining Center – KBT-15.A

Features an unmatched spindle diameter among machines of its class, enhancing efficiency in deep cavity machining, deep hole drilling, and multi-face machining.

A standard model within the 150 mm spindle diameter series.

Equipped with the highest-rigidity spindle available in horizontal boring and milling machining centers, delivering outstanding performance in spindle extension (W-axis) operations.

The spindle drive incorporates a 3-step gear transmission, providing high torque for powerful heavy-duty cutting

CNC Horizontal Boring and Milling Machining Center – KBT-15B.A

Equipped with a high-rigidity spindle, while increasing both table size and maximum load capacity, making it a highly reliable machine tool.

Compared with the KBT-15.A, the table size has been expanded to 2000 × 2200 mm, and the maximum workpiece load capacity has been increased to 20,000 kg.

Provides extended travel ranges:

Y-axis (spindle head vertical travel): 2300 mm

Z-axis (column cross travel): 1600 mm Expanding the machining envelope for large-scale workpieces.

The spindle drive features a 3-step gear transmission, delivering high torque for powerful heavy-duty cutting operations.

CNC Horizontal Boring and Milling Machining Center – KBT-15MAX / KBT-15HMAX

Designed to meet the machining requirements of large-scale workpieces, featuring a sliding-spindle design that delivers the renowned KURAKI rigidity.

Equipped with a square sliding-spindle headstock, enabling both spindle head movement and boring spindle (W-axis) movement, which greatly improves workpiece accessibility.

Various custom specifications can be provided according to customer requirements.

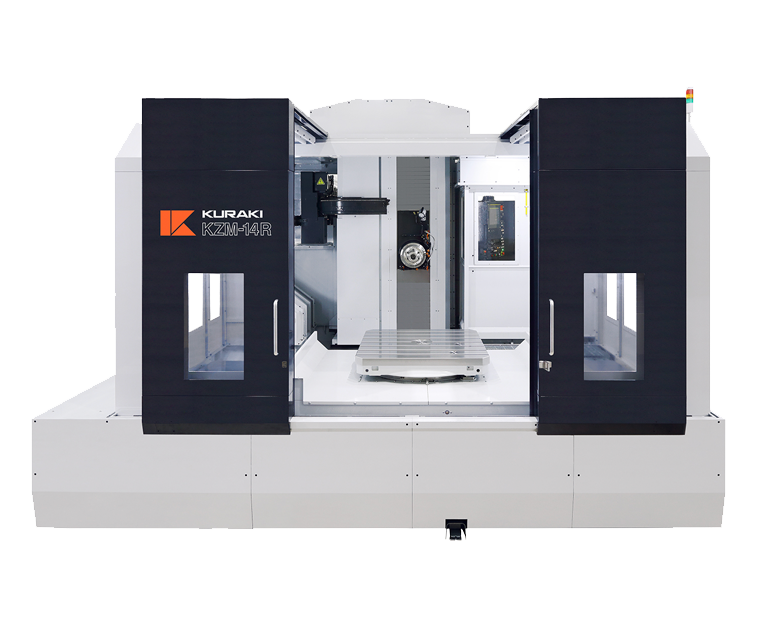

Horizontal Machining Center – KZM-14R

A large-inertia heavy-duty machining center offering the strongest cutting capability in its class, delivering advantages of power, speed, and space efficiency.

Significantly improves machining efficiency for mold applications and difficult-to-cut materials, especially in deep cavity and deep hole machining, while greatly reducing floor space requirements.

Equipped with a three-stage gear transmission, providing a maximum torque of 2123 Nm.

Achieves high rigidity through square sliding guideways

Horizontal Machining Center – KTR-1200

Capable of high-precision machining for a wide range of workpieces, from small components up to large parts of 1650 mm, without the need for repeated setups.

Equipped with a high-torque spindle, ideal for machining difficult-to-cut materials.

Utilizes the advantage of the boring spindle’s W-axis extension, making it more suitable for heavy-duty cutting operations compared to conventional 5-axis machining centers.

Supports simultaneous 5-axis machining, including table rotation (B-axis) and table tilting (A-axis).

By combining table tilting with the boring spindle’s W-axis extension, interference between the workpiece and cutting tools during machining is effectively prevented.

The advanced boring spindle extension (W-axis) ensures excellent rigidity while enabling precise internal machining of complex workpieces.

CNC Combined Boring and Milling Machining Center – CMN-5C

A single machine enables vertical and horizontal machining operations, significantly reducing workpiece setup time.

Equipped with dual spindles (vertical and horizontal), eliminating secondary clamping and maintaining exceptionally high squareness accuracy.

Note: except within the interference zone of the vertical and horizontal spindles.

With an optional rotary table, simple 5-axis machining can be achieved in one setup.

Chip evacuation is designed with a lateral discharge system parallel to the X-axis, effectively saving floor space.

The chip conveyor features three large openings, greatly improving chip removal efficiency.

Deep Hole Drilling Machine – KGD Series

A single machine enables composite machining operations, including gun drilling, counterboring, and conventional drilling.

Built upon a deep hole drilling spindle, the system is equipped with an additional boring spindle, allowing both counterboring and deep hole drilling to be completed in one setup.

The boring/milling spindle rivals the latest KBT series, delivering high torque, high power, and high rigidity machining performance for efficient processing of difficult-to-cut materials.

Capable of machining hole diameters from Ø5 mm to Ø42 mm.

KGD-1411Z: maximum drilling depth 1000 mm

KGD-2013: maximum drilling depth 1650 mm

Equipped with a high-precision rotary table, enabling indexing in 0.001° increments, suitable for machining aerospace-shaped holes and inclined holes.

Features anti-vibration guide assemblies (to prevent drill deflection), with interval positioning mechanisms that greatly suppress drill oscillation during deep hole machining.

Deep Hole Drilling Machine – KGM Series

A newly developed composite gun drilling machine, fully compatible with the latest tooling systems.

Equipped with two machining modes (GD, MC). A single spindle head supports gun drilling, machine gun drilling, counterboring, tapping, and milling operations.

In MC mode, the system also supports ATC (Automatic Tool Changer) functionality.

Integrated with a high-precision rotary table, enabling indexing in 0.001° increments, suitable for machining aerospace-shaped holes and inclined holes.

Features anti-vibration guide assemblies (to prevent drill deflection), with interval positioning mechanisms that significantly suppress drill oscillation during deep hole machining.

Product Introduction

From single-piece to mass production, this machine delivers high-quality, high-efficiency grinding performance.

Our proprietary control system enables 0.1 μm feed increments, ensuring superior proficiency in rotary grinding operations.

The unique gantry-type structure provides stable feed motion and guarantees high precision.

The grinding spindle moves along the gantry guideways, offering excellent operability and allowing control of wheel engagement geometry during cutting.

Operators can maintain their working position; the low magnetic chuck height facilitates easy loading and unloading of workpieces.

Vertical and longitudinal feeds are controlled by our proprietary control system combined with AC servo motors.

The minimum vertical feed setting can be configured at 0.1 μm.

Supports automatic grinding cycles: rough grinding → fine grinding → spark-out grinding → wheel stop at the workpiece periphery.

Even during automatic cycles, operators can add additional machining at step infeed, adjust worktable rotation speed, total grinding allowance, and wheel rotation speed.

PRG6DX, PRG8DX

Product Overview

Equipped with standard graphical conversational software, capable of performing up to four-step grinding operations.

Machining modes can be selected between continuous infeed or vertical plunge grinding.

Incorporates a unique gantry-type structure, ensuring stable feed motion and guaranteeing high precision.

The spindle moves along the gantry guideways, providing superior operability and enabling control of wheel engagement geometry during cutting.

Operators can maintain their working position; the low magnetic chuck height facilitates easy loading and unloading of workpieces.

Supports worktable tilting operations. With simple adjustments, the table can be inclined, making it suitable for machining convex/concave tapered components and cutting tools.

Following the guidance of the standard conversational interface, operators only need to input the required machining parameters to execute automatic grinding cycles.

PRG6DXNC, PRG8DXNC, PRG10DXNC, PRG12DXNC

Product Overview

Designed to meet the demands of the ultra-high-speed spindle era, this rotary surface grinder delivers high-precision machining, making it ideal for CD molds and precision cutting tools.

Capable of achieving parallelism/flatness of 0.3 μm and ultra-precision machining within Φ300 mm workpieces.

Features a variable hydraulic guideway system, an air-bearing worktable, and a top-grade rotary table.

The rotary table air bearing achieves accuracy of 0.05 μm in both radial and axial directions.

Constructed with ultra-precision components, the machine provides a minimum vertical feed increment of 10 nm.

Product Overview

Developed with the objective of achieving superior vertical accuracy and precise positioning, this is an eco-friendly form grinder that eliminates the need for waste oil treatment.

The minimum feed setting for vertical and longitudinal axes can be configured at 0.1 μm.

The cross and longitudinal axes adopt V-V guideways, with precision hand-scraped surfaces to ensure higher accuracy.

The spindle rigidity is 1.45 times greater than that of previous models.

The machine frame has been enlarged to enhance longitudinal stability, providing a high-rigidity specification.

A low hydraulic pressure design eliminates the primary cause of thermal deformation.

No waste oil treatment is required, achieving a CO₂ reduction effect of 199.2 kg.

Standard equipment includes digital linear scales on vertical and longitudinal axes.

A 2.2 kW spindle inverter, previously offered as an optional accessory on earlier models, is now provided as standard equipment.

Product Overview

The popular MM350 Form Grinder, widely used for machining mold components, now returns with an expanded machining range.

Built upon traditional grinding technology and proven through long-term operation, it delivers sensitive precision and reliability.

To enhance manual grinding performance with MM415 and MM420 models, a variety of optional accessories are available.

Equipped with a lightweight, smooth-operating handwheel, essential for manual grinding operations.

Features a high-rigidity specification with a standard 1.5 kW spindle motor, enabling applications from high-efficiency mold machining to fine form grinding.

Product Overview

Equipped with an independently developed control system, enabling automatic grinding cycles for form grinders.

Designed for fine machining of small workpieces such as molds or fixtures, as well as form grinding of complex-shaped components.

Available in three specifications to suit different applications:

PFG450DXA → Automatic traverse, longitudinal, and vertical feed

PFG450DXB → Automatic traverse and longitudinal feed

PFG450DXC → Automatic traverse feed

Product Overview

Optional automatic grinding cycle modes, designed as a high-rigidity form grinder.

The machine structure adopts a wide spindle shaft with ultra-precision ball bearings, providing outstanding rigidity and minimizing heat generation.

This construction is ideal for precise positioning control in the longitudinal direction.

Available configurations include:

Manual type (Standard / DXII type)

Automatic cross-feed (C type)

Automatic vertical and cross-feed (P type)

Full automatic (P type)

Full automatic with high-speed stroke (S type)

Configurations can be selected according to specific customer machining requirements.

The full automatic type supports an automatic cycle of rough grinding → fine grinding → spark-out grinding, with a minimum vertical feed setting starting from 0.1 μm.

Demonstrates excellent performance in the field of precision grinding applications.

PFG500II Series

PFG500PII · PFG500AII · PFG500CII

PFG500DXII Series

PFG500DXPII · PFG500DXAII · PFG500DXCII · PFG500DXSII

The machine features a simple text-based touch panel and automatic data input setting function, drastically reducing machining time. Okamoto’s proprietary software operating system supports profile grinding and compound machining, and is equally effective even for super-hard alloys.

Equipped with the same software system as the IGM15EXⅢ, once the wheel grit size and wheel width are entered along with the final workpiece outer diameter, the system automatically generates the optimal grinding and dressing conditions. No text input is required on the operation screen—operators simply follow the panel display and touch to complete setup. By adopting touch-screen control, unnecessary switch installations are eliminated, making operation more streamlined.

For the IGM15NCⅢ, optional two-axis cone and profile forming software is available. This enables not only complex grinding tasks but also saving of grinding conditions.

Compared with conventional dual-wheel spindle machines, the IGM15NCⅢ-2 allows step-hole, end-face, taper, and external grinding to be performed in a single clamping. This improves concentricity and squareness accuracy. Additionally, the feed axis adopts a closed-loop system with optical scale feedback, further enhancing dimensional precision.

The latest model internal grinder with parameter-saving capability, designed as a general-purpose machine for high precision, operability, high performance, and mass production suitability.

In addition to data input via LCD display, this model is the first to feature a selector switch function for setting worktable feed speed and grinding condition variations. It resolves the conflict between general-purpose machine operation and specialized data recording, allowing storage of up to 36 machining parameter sets.

The worktable and guideway drive adopt a ballscrew and linear guide system, ensuring accurate positioning of internal surfaces, repeatability with high precision, and structural rigidity. A low hydraulic pressure temperature management system reduces maintenance inconvenience and replacement issues.

Worktable position data input is performed on the operation screen using graphic symbol indexing for intuitive setup.

IGM2TNCⅢ: A large internal grinder capable of machining workpieces up to 1000 mm in length, with a spindle that can rotate up to 15°.

IGM2TNC-3/4: Designed for machining workpieces ranging from 1000 mm to 2000 mm in length (other specifications available upon request).

Equipped with graphical conversational software, the machine can perform up to 8 continuous grinding cycles. The reverse travel position of the worktable and the initial infeed position can be set either by entering key data or by tool-touch positioning. When the workpiece length changes, the grinding spindle head can be switched left or right accordingly.

During automatic cycles, dressing, cycle interruption, and retraction operations can be performed. Depending on conditions, end-face grinding of long workpieces can also be carried out.

This compact vertical internal grinder is designed for high productivity, targeting batch production of medium-sized automotive components. With an opening kept under 1 meter, the machine achieves a slim profile with an 840 mm opening, allowing mechanical details to be clearly visible.

The vertical feed system and a worktable travel speed of up to 15 m/min enable high-speed contact. Equipped with an advanced reciprocation capability of 490 strokes per minute (with a 2 mm stroke width), the cycle time is dramatically improved.

Optional equipment includes a compact vertical multi-joint robotic measuring device outside the machine. This enables continuous operations of workpiece replacement → cleaning → measurement → correction, ensuring efficient and automated production.

Featuring a high-rigidity structure and user-friendly operating software, this machine is upgraded for angular grinding applications. It enables simultaneous grinding of external diameters and end faces, significantly reducing machining time.

The angular design (wheel spindle fixed at 30° on the right end) maximizes utilization of the wheel periphery, allowing more efficient end-face grinding of workpieces. During grinding cycles, dressing operations can be integrated. The machine supports both manual single-piece machining and automated batch processing, giving operators full flexibility in operation.

A highly acclaimed general‑purpose non‑NC external grinding machine, designed to maximize operator visibility and ease of use. Its operability has been recognized worldwide.

The worktable feed (left‑right) and wheel infeed (handwheel control) are both manually operated, ensuring straightforward handling and flexibility. The machine is equipped with the same control system used in surface grinders, providing reliability and consistency.

Although classified as a general‑purpose model, it also supports digital management functions, enabling integration into modern production workflows.

Equipped with a grinding spindle capable of external, angular, and internal machining, this machine enables composite grinding operations in a single setup, significantly reducing machining time.

With the spindle supporting external diameter, angular surface, and internal bore grinding, the machine performs continuous external, face, and internal grinding under automatic spindle rotation, all in one clamping cycle.

The system is equipped with in‑process measurement and automatic compensation functions, enabling high‑precision automatic cycle grinding.

The machine frame adopts a T‑shaped monolithic structure, eliminating overhang, ensuring stable grinding performance and superior accuracy.

A direct‑drive (DD) motor controls spindle rotation, providing precise positioning and guaranteeing ultra‑high accuracy grinding.

UGM360NC, UGM3100NC

A composite grinding machine designed for large workpieces, capable of performing continuous internal, external, and end‑face grinding operations. With a single setup, the machine enables internal diameter, external cylindrical, and face grinding, ensuring high angular accuracy and superior roundness.

The compact design saves floor space while maintaining rigidity and functionality. The grinding spindle automatic rotation and ATC (Auto Tool Changer) are provided as standard specifications.

Additionally, the machine is equipped with a rotary dresser for large‑diameter grinding wheels, ensuring precise wheel conditioning and stable machining performance.

A vertical ultra‑precision multi‑function grinding machine designed for large workpieces. This vertical composite internal grinding machine achieves exceptional roundness accuracy.

The work spindle is supported by an air‑bearing system, enabling astonishing roundness even for workpieces with an internal diameter of 300 mm.

Optional equipment includes an AWC (Auto Work Changer). The grinding wheel spindle manual rotation is provided as a standard specification.

Designed to enhance high‑precision cylindrical grinding by improving the roundness of center holes, this machine ensures accurate reference alignment between the workpiece center and its center hole—critical for precision machining. If the center hole lacks proper roundness, the workpiece center shifts during rotation, making true precision machining impossible.

The spindle is equipped with a variable‑frequency drive (up to 40,000 rpm) as standard. The wheel forming angle range has been significantly expanded from conventional models, now covering 0° to 180°.

By utilizing a high‑precision grinding wheel in rotation, machining can be performed even without rotating the workpiece, thereby saving both labor and time.

CHG600P, CHG1000P, CHG1200P, CHG1500P

The UPZ315Li / UPZ52Li ultra‑precision profile grinding machines feature a linear motor‑driven worktable, delivering high performance, high rigidity, and high‑speed profile grinding.

With high‑speed reciprocating motion, the machine enables micro‑profile grinding and supports multi‑position grinding, making it ideal for small‑lot, multi‑variety production. It achieves reversal accuracy within 1 μm, ensuring precise positioning.

Equipped with CCD camera and probing systems, the machine supports in‑process measurement and inspection. The low‑overhang T‑shaped monolithic frame design minimizes thermal displacement, while three‑axis closed‑loop control enhances machining stability and accuracy.

The operating software is independently developed, providing intuitive programming and control. The machine supports:

Wheel profile grinding

Multi‑position grinding

Contour grinding

Vertical plunge grinding and other grinding modes

The ultimate ultra‑precision profile grinding machine, equipped with dual‑axis linear motor drives, enables seamless transition from rough grinding to finish grinding without the need to change wheels.

Because workpieces mounted on an ATC (Automatic Tool Changer) are difficult to swing and must maintain balance and reference alignment, conventional setups are not suitable for micro‑profile grinding. Therefore, a dual‑axis configuration is typically required.

With an inclined spindle head, the machine can perform bilateral surface machining. By employing separate wheels for rough grinding and fine grinding, it can efficiently process both sharp corners and R‑shaped profiles. The system is also compatible with APC (Automatic Pallet Changer).

A CCD camera system provides image processing capability, recording the transition from the initial reference position to the machining position, thereby eliminating errors that may occur during pallet exchange.

The integrated cycle—CAD data input → micro‑profile machining → CCD automatic measurement → tolerance grinding → automatic workpiece exchange—realizes complete digitization and automation of micro‑grinding operations.

Product Overview

The UPZ210LiII ultra‑precision micro profile grinding machine is equipped with three‑axis linear motor drives, delivering enhanced accuracy and stability for fine mold machining. Developed specifically for micro‑mold applications, this upgraded model builds upon the proven UPZ210Li platform, offering further improvements in both performance and operability.

Unlike conventional grinders, all three axes—X (left‑right), Y (front‑back), and Z (up‑down)—are driven by linear motors, ensuring superior precision and stability across each axis.

The machine supports CAD data input prior to machining, simplifying programming and setup. It is also equipped with 3D contour machining capabilities, enabling efficient processing of complex and special‑shaped workpieces. By simply selecting the machining start and end positions, the system automatically generates G‑code programs, eliminating the need for manual trajectory settings as required in optical profile grinders.

Standard functions include vertical plunge grinding and continuous plunge grinding cycles for rough machining, significantly reducing overall processing time.

Featuring an independently developed adhesive-type column structure, this machine is designed to support high-precision profile grinding operations. Unlike conventional grinders in the industry, it adopts our proprietary column design, ensuring long guideways with superior static rigidity (GH) for stable machining performance.

The machine is capable of performing a wide range of operations, including surface grinding, profile grinding, and mirror-finish grinding. Maximum vertical grinding capacity reaches 317.5 mm (with a magnetic chuck height of 80 mm).

It enables not only side machining of mold components for electronic parts such as inserts, but also edge machining, upright machining, and ultra-precise six-face machining.

Equipped with a standard three-direction dressing unit, the system allows operators to select the optimal dressing method according to the workpiece geometry. Multiple combined dressing and grinding cycle modes can be easily programmed and executed, ensuring both flexibility and efficiency in machining.

A high‑rigidity gantry‑type surface grinding machine designed to meet the demands of high‑precision and high‑efficiency machining. It is ideally suited for large automotive molds and LCD components, addressing the mold manufacturing industry’s requirements for short delivery times and high productivity.

The machine is equipped with a globally standardized, user‑friendly text‑based software interface, allowing operators to input data via touchscreen while simultaneously monitoring on‑screen icons, ensuring simple and intuitive operation.

For the first time in the surface grinding field, the CH‑iQ series incorporates an automatic data generation function. By entering the total grinding stock removal and the in‑process removal amount, along with the grinding wheel grit size, the system automatically generates the most suitable grinding and dressing parameters based on grinding theory and machining experience.

The combination of coarse wheel dressing using the overhead dresser and fine finishing with the table‑mounted dresser significantly reduces dressing time. In addition, the automatic cycle time for plunge grinding is shortened. Compared with conventional overhead dressing alone, the integrated coarse‑fine dressing method with the table dresser further minimizes overall machining time.

PSG158CH‑iQ, PSG208CH‑iQ, PSG308CH‑iQ, PSG408CH‑iQ

A compact, high-rigidity gantry-type surface grinder, designed for multi-process machining applications. This series includes:

PSG-CVNC: Vertical rotary axis specification

PSG-CHVNC: Dual-head spindle specification (Horizontal & Vertical)

Featuring a patented crossbeam structure developed in-house, the machine allows precision restoration and adjustment without disassembly or CNC compensation, ensuring minimal downtime and high repeatability.

The CHNC and multi-process series are engineered as compact machining centers that eliminate the need for large bed-type gantry grinders. Each unit is custom-built to meet specific user requirements.

Ideal for components demanding ultra-low surface roughness—such as LCD-related parts, spray nozzles, and coating system components—these machines support post-grinding polishing operations when necessary.

Additionally, we offer machines capable of free-abrasive processing, providing tailored solutions for specialized finishing applications.

Model Series: PSG2010CHNC, PSG3010CHNC, PSG2015CHNC, PSG3015CHNC, PSG4015CHNC, PSG3020CHNC, PSG4020CHNC

This gantry-type surface grinder is optimally designed for compound guideway surfaces of machine tools. To achieve high-precision machining across the full table size and maintain straightness, the crossbeam is equipped with a special structure independently developed by our company. Once the machine is fully assembled, adjusting the straightness of the crossbeam is normally very difficult. With our proprietary beam design, even after many years of operation, precision can be restored without disassembling the crossbeam.

Optional attachments are available for convex and concave profile grinding, enabling efficient curved surface machining and significantly reducing tooling time.

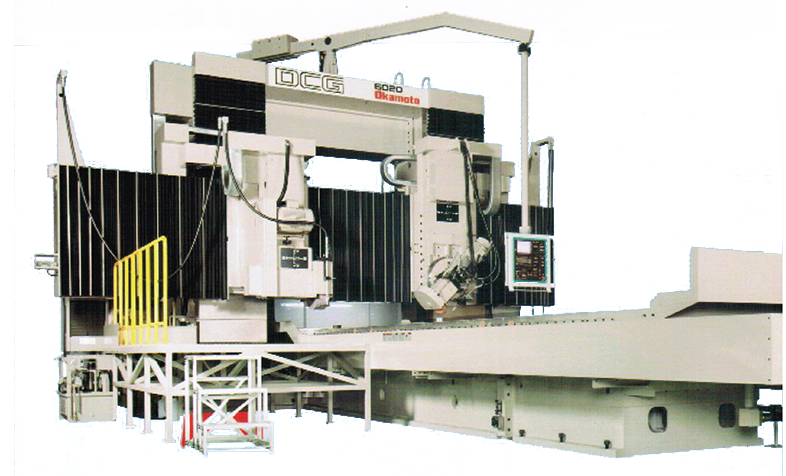

DCG4015NC, DCG6015NC, DCG8015NC, DCG10015NC, DCG4020NC, DCG6020NC, DCG8020NC, DCG10020NC

The world's largest gantry-type surface grinder, engineered for ultra-high precision planar grinding. Achieves a surface flatness of 30 nm/m², with a machining envelope of 10 meters in length and 3.5 meters in width (expandable to 4 meters). This machine represents the largest bed-type grinding system globally.

Key features include:

Fully hydrostatic guideway system for all axes, ensuring friction-free motion and exceptional stability

Independently developed variable hydrostatic guideways on the table’s longitudinal axis and crossbeam, allowing dynamic control of oil flow based on load conditions

This system minimizes oil film variation across the guideway surfaces, maintaining consistent height differentials across the entire table span

Precision specifications:

Straightness accuracy of reference surfaces:

Longitudinal (X-axis): ≤ 0.5 μm/m

Transverse (Y-axis): ≤ 0.5 μm/m

This machine is purpose-built for ultra-large workpieces requiring nanometer-level surface integrity and sub-micron geometric precision.

Designed to enhance the accuracy of tooth profile, lead, and pitch, this series achieves gear machining precision equivalent to legacy JIS 0-grade standards.

Key improvements include:

Spindle motor upgrade from belt-driven to built-in direct drive, controlled via a high-resolution encoder with three times the resolution of previous models

Forming feed axis encoder resolution also tripled, significantly improving tooth profile accuracy

Work axis encoder mounted directly beneath the work spindle, with enhanced resolution to minimize synchronization error and improve pitch accuracy

To mitigate thermal deformation, the tailstock incorporates low thermal expansion castings, ensuring dimensional stability during high-precision machining.

The mechanical structure is optimized for ultra-precise gear grinding applications. The machine supports automatic wheel profiling, auto dressing, and automatic grinding cycles via newly integrated functional standards.

The dual-rotary dresser system reduces dressing time and extends the life of the diamond dressing tool.

Model Series: SHG360NCS ・ SHG400NCS

Equipped with the globally acclaimed touchscreen input interface and interactive dialog system (iQ), this series offers intuitive operation and streamlined setup. The system enables automatic configuration of grinding and dressing parameters, with graphical interface support that significantly reduces data input time.

Supported grinding modes include:

Surface grinding

Slot and groove machining

Profile grinding

Form grinding

When using the overhead dresser configuration, combined with rough and finish grinding processes, cycle time is further reduced compared to conventional table-mounted dressing methods.

For models with hydrostatic spindle customization, mirror-finish grinding requirements can be achieved with exceptional surface quality.

Model Series: PSG63CA-iQ ・ PSG64CA-iQ ・ PSG66CA-iQ ・ PSG84CA-iQ ・ PSG104CA-iQ ・ PSG106CA-iQ

Equipped with advanced proprietary technologies accumulated through years of dedicated machine development, this series supports simultaneous 2-axis and 3-axis CNC control, enabling optimized automation for indexing, measurement, and multi-process machining.

The machine features a monolithic T-frame structure:

X-axis (left-right): Configurable with either V-V slideways or linear ball guideways depending on machining requirements

Y-axis (front-back) & Z-axis (up-down): Employ direct-drive linear ball guideways for high-precision motion

The X-axis is driven by a hydraulic system, and the worktable slideways are fully supported throughout the stroke, eliminating overhang and ensuring stable machining even during full-range table movement.

Both Y and Z axes offer high-accuracy positioning, allowing precise machining of complex-shaped workpieces. With a proven track record across diverse applications, the machine supports tailored grinding solutions for various components.

By leveraging simultaneous 2-axis control, it achieves grinding performance comparable to precision profile grinders.

Model Series: PSG66CA2 ・ PSG106CA2

Simultaneous 2-axis and 3-axis control CNC machines feature ball screw-driven worktables, supporting a wide range of grinding and in-process measurement capabilities. The machine adopts a monolithic T-frame structure, enabling X, Y, and Z axes to operate via precision ball screw or direct-drive linear motion systems.

Supported grinding operations include:

Standard surface grinding with automatic cycles

Continuous feed grinding

Plunge grinding

Multi-directional grinding

Profile grinding (concave/convex)

Taper grinding

High-speed and low-speed grinding

The machine can be equipped with an indexing device for rotary positioning and multi-face machining. The table incorporates three-directional standard dressing units, with optional rotary dresser and oscillating dresser configurations available.

Worktable drive utilizes a precision ball screw mechanism. Optional configurations include:

Touch probe measurement systems

CCD camera-based measurement systems

These enable in-situ measurement and grinding without removing the workpiece. Through simultaneous 3-axis control, the machine achieves grinding performance equivalent to precision profile grinders, offering optimal solutions for diverse workpiece geometries.

Model Series: PSG64CA3 ・ PSG84CA3 ・ PSG104CA3

Column-Type Structure · High Rigidity · Closed-Loop Control for Precision Profile Grinding

This compact CNC profile grinding machine features a high-rigidity column-type structure, with a mass 2.1 times greater than previous models. Its low-overhang design significantly enhances vibration damping, enabling stable and ultra-precise machining.

The conversational control software integrates decades of accumulated grinding know-how, supporting advanced grinding modes such as groove grinding, composite grinding, and contour/profile grinding. Optional accessories further enhance groove accuracy and repeatability, making it ideal for high-precision mold components and tooling applications.

Smart Surface Grinding for Large Workpieces — Powered by iQ Software

This advanced surface grinding series leverages proprietary iQ software to simplify and optimize the machining of large workpieces. Grinding and wheel dressing parameters are automatically configured, while the graphical touchscreen interface dramatically reduces data input time and enhances operational efficiency.

iQ intelligent control system enables automatic setting of grinding and dressing conditions.

Graphical touchscreen interface streamlines operation and minimizes setup time.

Ideal for large-scale precision grinding, offering both ease of use and high productivity.

Designed for flexible production environments, including custom machining and high-mix manufacturing.

PSG126-iQ, PSG156-iQ, PSG206-iQ, PSG306-iQ, PSG157-iQ

CNC Profile Grinding with Proven Machining Performance

This CNC profile grinding series is backed by extensive machining achievements and is capable of generating complex grinding processes with high precision. Designed for ultra-accurate machining of precision mold components, jigs, and fixtures, it delivers consistent quality and process reliability.

Supports CNC-controlled profile grinding, enabling automated generation of grinding paths and process parameters.

Proven performance in precision machining of mold parts, jigs, and high-tolerance components.

Ideal for applications requiring tight dimensional control, fine surface finishes, and repeatable accuracy.

Suitable for tooling, die manufacturing, precision engineering, and fixture production.

PSG52DXNC, PSG63DXNC, PSG64DXNC, PSG65DXNC, PSG84DXNC, PSG105DXNC

High-Efficiency Surface Grinding for Both Precision Parts and Large Workpieces

This versatile surface grinding series is engineered for high-efficiency machining of both small precision components and large industrial workpieces. As a foundational platform for mass production and custom configurations, it offers a wide range of models to meet diverse manufacturing needs. Backed by extensive machining experience, the series delivers optimized grinding solutions tailored to each user's application.

High-efficiency grinding performance across a wide range of workpiece sizes and materials.

Flexible platform suitable for both mass production and customized specifications.

Proven track record in precision surface finishing, tooling, mold making, and heavy-duty industrial applications.

Comprehensive model lineup enables selection of the most suitable machine based on actual machining requirements.

PSG125DXNC, PSG155DXNC, PSG205DXNC, PSG305DXNC, PSG126DXNC, PSG156DXNC

PSG206DXNC, PSG306DXNC, PSG157DXNC, PSG207DXNC, PSG307DXNC, PSG138DXNC

PSG158DXNC, PSG208DXNC, PSG308DXNC

Ultimate Precision Surface Grinder — Pushing Accuracy to the Limit